- Joined

- Jun 16, 2014

- Messages

- 13

Hi, I haven't posted for a while since I finished the Bolton #12 I decided to

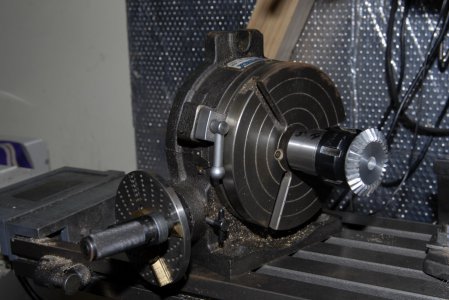

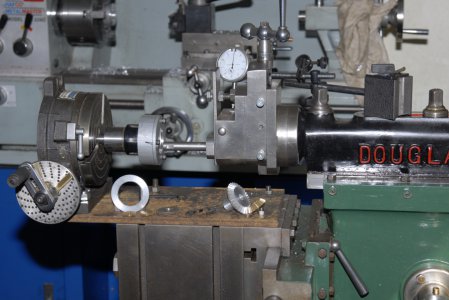

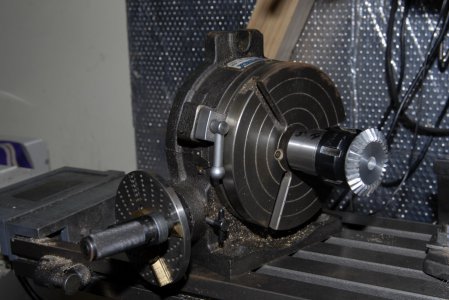

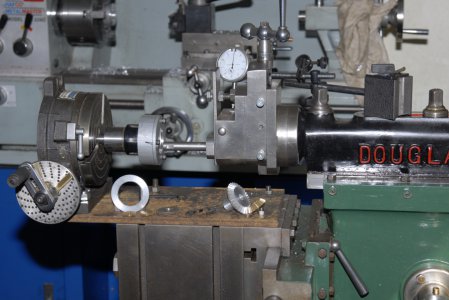

go back to the first engine I started to build and never finished, an Elmer's Geared (Hypocycloidal) Steam Engine, it was never finished because of the internal gear that is required, I ordered one from Boston gears USA(big dollars)but they sent the wrong one, external instead of internal so I moved on, now I want to show my setup for cutting internal gears also some bevel gears for the Bolton#12,

I made the internal gear with a single point cutter mounted in a shaper, to get the correct profile cutter I cut two teeth from an involute circular cutter and ground it down to one tooth with a square stub to mount in the end of a rod mounted in the shaper, the involute cutter cost $15 and you can get about 6 single tooth cutters out of it, it worked out well, some photos of my gear cutting,

John.

go back to the first engine I started to build and never finished, an Elmer's Geared (Hypocycloidal) Steam Engine, it was never finished because of the internal gear that is required, I ordered one from Boston gears USA(big dollars)but they sent the wrong one, external instead of internal so I moved on, now I want to show my setup for cutting internal gears also some bevel gears for the Bolton#12,

I made the internal gear with a single point cutter mounted in a shaper, to get the correct profile cutter I cut two teeth from an involute circular cutter and ground it down to one tooth with a square stub to mount in the end of a rod mounted in the shaper, the involute cutter cost $15 and you can get about 6 single tooth cutters out of it, it worked out well, some photos of my gear cutting,

John.