- Joined

- Oct 15, 2011

- Messages

- 153

You are right about the tool rests.

Most recently manufactured bench grinders seem to be fitted with those postage stamp sized pressed metal abomination tool rests with the tensile strength of dried peanut paste.

I opted for a larger working surface than most using 65 x 65 x 6 (2 1/2" x 2 1/2" x 1/4") angle iron screwed to a piece of slotted 25 x 6 flat bar (1"x 1"x 1/4" )

which bolts to the inner section of the wheel guard.

This permits horizontal adjustment for wheel diameter and angular adjustment on the single bolt pivot.

As most of my applications are for hand grinding of twist drills and HSS lathe tools, the combination suits me perfectly. All work was completed with hand tools and a drill press and linisher.

No pics until I go into the shed tomorrow morning.

Edit

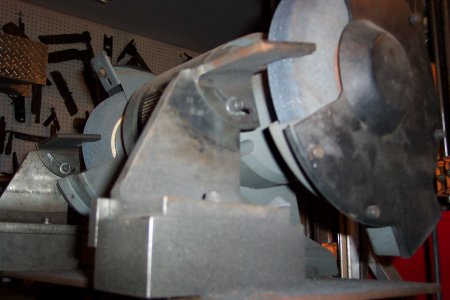

As promised - pic of tool rest

Most recently manufactured bench grinders seem to be fitted with those postage stamp sized pressed metal abomination tool rests with the tensile strength of dried peanut paste.

I opted for a larger working surface than most using 65 x 65 x 6 (2 1/2" x 2 1/2" x 1/4") angle iron screwed to a piece of slotted 25 x 6 flat bar (1"x 1"x 1/4" )

which bolts to the inner section of the wheel guard.

This permits horizontal adjustment for wheel diameter and angular adjustment on the single bolt pivot.

As most of my applications are for hand grinding of twist drills and HSS lathe tools, the combination suits me perfectly. All work was completed with hand tools and a drill press and linisher.

No pics until I go into the shed tomorrow morning.

Edit

As promised - pic of tool rest

Last edited: