A

Andre

Forum Guest

Register Today

This has become quite the endeavor. You ought to be proud of what you've done so far, Andre. What's really neat is how it's made from an assembly, from the dovetail to the cross slide screw.

Thank you!

I'm using what I have, plate and bar stock and screws. It was actually DonB that informed me of using plates to make it. He was telling me about a magazine article making a homemade lathe, and I'm sorta using it as an inspiration to build mine. Thanks again, Don!

*******************************UPDATE**********************

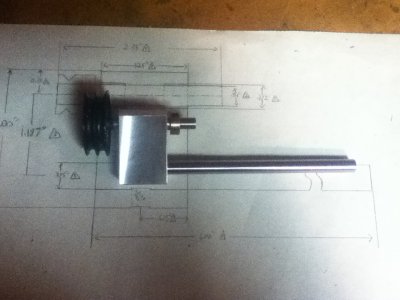

Today I drilled, counterbored, and tapped for the bearing adjustment. I also am changing from a round single split bearing to a double split, two piece bearing. The single split bearing was too snug on the spindle and kept turning. The double split two piece bearing didn't spin even at 2800 RPM and lets the spindle turn by hand, which the one piece bearing did not. And makes bearing wear adjustment more sensitive.

Drilling for the 1/4-28 bearing adjustment setscrew.

Since I'm drilling perpendicular to the hole i drilled for the round bed, I have to stop when I break through this wall, re center drill the other side, and continue drilling to prevent the drill from walking.

Here you can see what I mean.

Now since this hole is about 1.6" deep, I need to counterbore for the shank of the tap to get to the bottom of the hole. I didn't feel like grinding the shank of this tap down so I just counterbored it. It also saves time assembling it not having to thread a 28 pitch screw down an inch and a half.

NOTE: I'm counterboring with and endmill for a reason, I'm drilling into the back of the blind hole I drilled for the bed, and if I used drill it would've flexed against the back of the hole. Try drilling halfway into the side of a board if you don't believe me. So I'm using an endmill because it cuts on the side, so any flex there will be self correcting as the tool flexes back to it's normal state.

Tapping for the set screws. I'm not using the machine to tap it because in this case it's impossible (with the counterbore) to start the tap crooked.

Now I assemble it and lap the bearings in on my wood lathe running at 2800 RPM. I still have to finish this tomorrow to wear in the bearings a hair more.

That's it for today.