- Joined

- Sep 1, 2020

- Messages

- 1,586

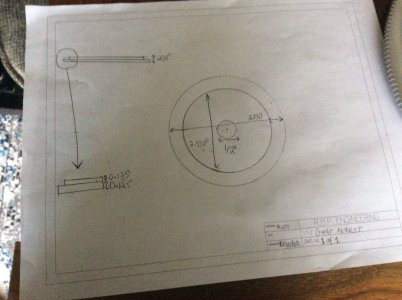

I want a bandsaw but no space want a power hacksaw but no money but with metal I was given along with some gears I’m starting to build a power hack saw . I have no u channel but some 2.5in by 3in angle that I will use. I have some more metal but it is 3in by 3in by 72in by 1/4in hot rolled each piece is $60 so no wasting any. I have a 1/6 hp motor 1725 rpm got it for 5 bucks at a flea market it is really heavy from about the thirty’s it is 16 lbs 35kg really heavy for 1/6hp all cast iron. I will make the hacksaw frame out of 3/16in aluminum

EDIT 35 LBS 16 KG

EDIT 35 LBS 16 KG

Attachments

Last edited: