- Joined

- Jan 2, 2019

- Messages

- 6,489

I'm sure some of you have seen my posts in the general section about this project.

www.hobby-machinist.com

www.hobby-machinist.com

But now that I'm ready to start on the controls I figured it would fit better here (mods please let me know if there's a more appropriate place).

I got a nice package of NEMA 23 stepper motors from a fellow member here and am about ready to jump into it.

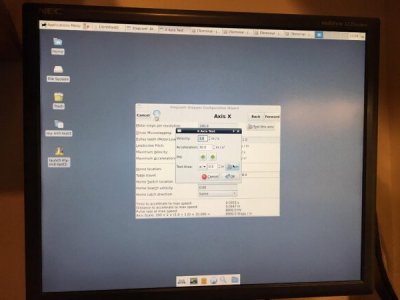

I already have my PC setup with LinuxCNC and a parallel card, PCI video card is on the way too since the onboard video may be problematic.

I'm currently working with this ST-V3 breakout board.

https://www.amazon.com/gp/product/B0093Y897A/ref=ppx_yo_dt_b_asin_title_o02_s01?ie=UTF8&psc=1

and these TB6600 stepper drivers

https://www.amazon.com/gp/product/B06XSBB45M/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

My plan is to keep things fairly simple and try to get everything talking first before working on the mountings.

Any and all comments, criticism, suggestions, etc. is appreciated since I've never done anything remotely like this before.

Cheers,

John

Homemade vertical mill drill

ericc, just curious what head you used? I own a Pratt & Whitney 3C bench horizontal mill and I want a vertical head. I am actually gathering parts for a home-made version based on some I have seen on Youtube. Thx

www.hobby-machinist.com

www.hobby-machinist.com

But now that I'm ready to start on the controls I figured it would fit better here (mods please let me know if there's a more appropriate place).

I got a nice package of NEMA 23 stepper motors from a fellow member here and am about ready to jump into it.

I already have my PC setup with LinuxCNC and a parallel card, PCI video card is on the way too since the onboard video may be problematic.

I'm currently working with this ST-V3 breakout board.

https://www.amazon.com/gp/product/B0093Y897A/ref=ppx_yo_dt_b_asin_title_o02_s01?ie=UTF8&psc=1

and these TB6600 stepper drivers

https://www.amazon.com/gp/product/B06XSBB45M/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

My plan is to keep things fairly simple and try to get everything talking first before working on the mountings.

Any and all comments, criticism, suggestions, etc. is appreciated since I've never done anything remotely like this before.

Cheers,

John