Hi all,

I need to spline the end of a shaft to accept a sprocket, I have lathe and mill but I don't have an indexer. I have a collet block that I could cut the initial groove but I'm drawing a blank on how to re-index the shaft to cut the strait sides on the remaining teeth. My thought was to cut the groove then index it 30 degrees and offset both ways to cut the sides parallel and to width.

Would one of the cheap spin indexers work for something like this?

I think it is a parallel key spline, is that correct?

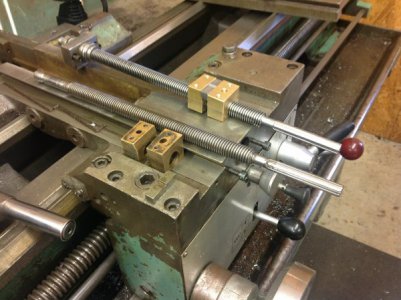

Here is a pic of the sprocket.

I need to spline the end of a shaft to accept a sprocket, I have lathe and mill but I don't have an indexer. I have a collet block that I could cut the initial groove but I'm drawing a blank on how to re-index the shaft to cut the strait sides on the remaining teeth. My thought was to cut the groove then index it 30 degrees and offset both ways to cut the sides parallel and to width.

Would one of the cheap spin indexers work for something like this?

I think it is a parallel key spline, is that correct?

Here is a pic of the sprocket.