- Joined

- Sep 24, 2012

- Messages

- 484

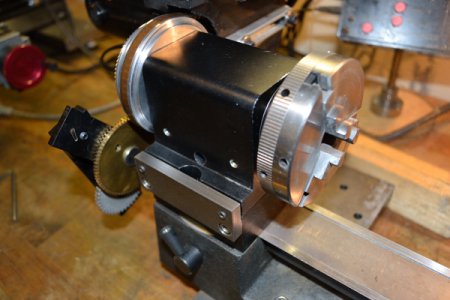

Hey guys - I need to replace my #1041 Sherline chuck (the 2-1/2" diameter with 3/4"-16 threads) because my old one has runout that is unacceptable. I've dismantled, cleaned & oiled it at least twice now, and the chuck still throws a piece of drill rod more than .006" measured 2" away from the jaws.

How can I acquire a new one (same model) and be assured of better runout specs? I'll have to order online because there's no local dealers. It seems awkward to contact one of the sellers and say "hey would you sort through all your inventory and sell me the best one". I'd hate to resort to that.

I guess Sherline chucks are "built to a price point", meaning I can't expect the specs I might get from a higher quality brand.

PS - if I can find an acceptable #1041, I'll keep my old one and try to stone the jaws until I get better TIR. I've never tried that and I expect it will be a tedious, trial-and-error project. If I succeed, I'll keep it as a backup. If I botch it - well, I have room for it in the circular file (cringe!).:angry:

How can I acquire a new one (same model) and be assured of better runout specs? I'll have to order online because there's no local dealers. It seems awkward to contact one of the sellers and say "hey would you sort through all your inventory and sell me the best one". I'd hate to resort to that.

I guess Sherline chucks are "built to a price point", meaning I can't expect the specs I might get from a higher quality brand.

PS - if I can find an acceptable #1041, I'll keep my old one and try to stone the jaws until I get better TIR. I've never tried that and I expect it will be a tedious, trial-and-error project. If I succeed, I'll keep it as a backup. If I botch it - well, I have room for it in the circular file (cringe!).:angry: