- Joined

- Oct 30, 2016

- Messages

- 155

I'm going to make a fixture to hold a piece of nickel silver to make a cork check for a fly rod reel seat.

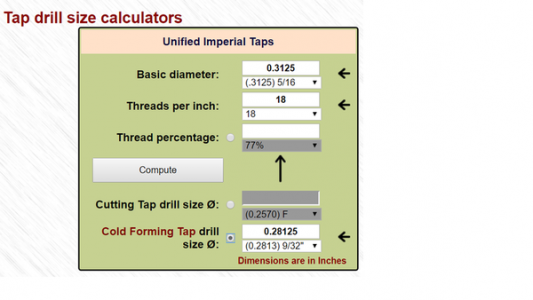

The short story is that I need to drill a hole to tap for a 5/16 socket cap screw of 18 TPI. Is there a standard size hole I should drill for the tap and how can I find out what it should be?

Also, is there a table with all this data available for a newbie such as me that's understandable?

Any help appreciated,

cheers

The short story is that I need to drill a hole to tap for a 5/16 socket cap screw of 18 TPI. Is there a standard size hole I should drill for the tap and how can I find out what it should be?

Also, is there a table with all this data available for a newbie such as me that's understandable?

Any help appreciated,

cheers