- Joined

- Nov 16, 2014

- Messages

- 56

Hey guys --

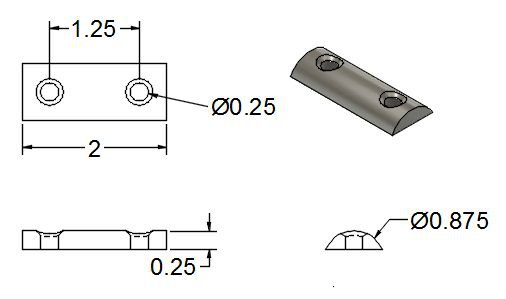

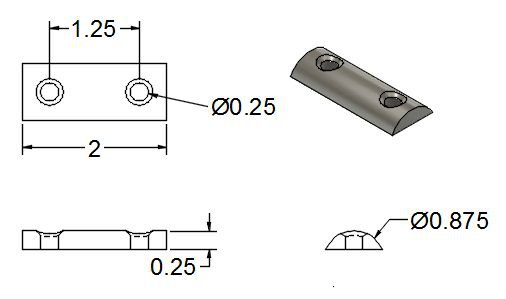

I need to make this part out of delrin. It adapts a control lever that is designed to fit on 7/8 tube to bolt to a square tube. I can hold the 7/8 round stock in a v-block to drill the holes, then split it to rough thickness with a bandsaw. But then how do I hold it to mill off the flat to finish thickness? I thought maybe tap the holes 1/4-20 and bolt it to a plate I could clamp in the vise. That seems like there must be an easier way.

Any suggestions?

Thanks in advance.

Leon

I need to make this part out of delrin. It adapts a control lever that is designed to fit on 7/8 tube to bolt to a square tube. I can hold the 7/8 round stock in a v-block to drill the holes, then split it to rough thickness with a bandsaw. But then how do I hold it to mill off the flat to finish thickness? I thought maybe tap the holes 1/4-20 and bolt it to a plate I could clamp in the vise. That seems like there must be an easier way.

Any suggestions?

Thanks in advance.

Leon