- Joined

- Jan 11, 2013

- Messages

- 1,821

Am I losing my mind here?

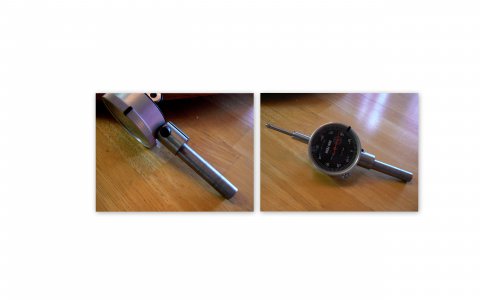

Both .0005 dial indicators I have are without any obvious means (to me) of mounting? Most .001 indicators have a hub on the back or something.

I want to make a mount to follow the headstock of the surface grinder to more accurately keep track of head movement. I can also see how accurate this Y (vertical on a grinder) screw is after all these years.

Pics below! Thanks for any help anyone!

Bernie

Both .0005 dial indicators I have are without any obvious means (to me) of mounting? Most .001 indicators have a hub on the back or something.

I want to make a mount to follow the headstock of the surface grinder to more accurately keep track of head movement. I can also see how accurate this Y (vertical on a grinder) screw is after all these years.

Pics below! Thanks for any help anyone!

Bernie