- Joined

- Oct 5, 2010

- Messages

- 1,043

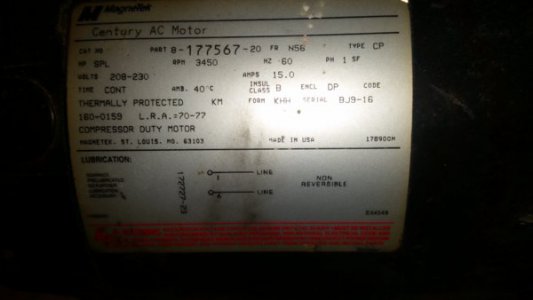

I have a wood planer that needs a motor, but the motor needs to turn clock wise. I have a 5hp compressor motor that states that it's "non-reversable". Of course it only turns counter clock wise. Yes I know that I could reposition it 180 degrees, but that option is out. Is there an electrical means to get that motor to turn the other way? Or does someone make a make a mechanical device to do the same?

TIA

Randy

TIA

Randy