I've had this lathe about a year now and for the first time last week I used the tail stock to center drill a hole in a work piece... I only have a 4-jaw chuck so I am forced to dial in all my work pieces before doing any turning. I diled in the piece and set up the tailstock with a .25" end mill to cut a .25" hole. Everything went smoothly but when I measured the hole it was .285" instead of .25". I had noticed earlier that day when parting off a piece that the cutter was low and left a tab on the end of the work piece. I set up my cutters by centering them on the point of the tailstock and assumed it was set at the center height of the spindle. Evidently my tailstock is .035" low. how to I set the correct height?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How To Align Tailstock On Rockwell 14x40

- Thread starter Timgunner

- Start date

- Joined

- Dec 25, 2011

- Messages

- 10,503

I'm not familiar with the Rockwell, but if the tailstock can be offset to turn a taper, then it should have a base that the main casting sits on. Buy a sheet of brass shim stock and cut out a piece to fit without interfering with the offset capability. However, 0.035" sounds like a bunch to be off unless that isn't the original tailstock.

- Joined

- Sep 25, 2014

- Messages

- 1,106

Well if the 0.25" end mill makes a 0.285" hole then it would be 0ff by 0.0175". I'd agree with Robert, that is a lot for the tailstock to be out (whether low, high or side to side, you'll get the same result). Have you gone through the tailstock alignment activities. One quick method that will get you within a few thou is just a small metal ruler on the flat between the center points. If it is out and low by that much, the ruler will be leaning a whole bunch to the right.

For setting your part off tool, try starting off a bit low, then make a few test cuts, adjusting until the pip is gone. Then leave the part off tool set in that holder (or take a measurement down to some reference and write it on the tool - could even get fancy and make up a height tool specific to setting the cutting tool elevation for your machine).

For setting your part off tool, try starting off a bit low, then make a few test cuts, adjusting until the pip is gone. Then leave the part off tool set in that holder (or take a measurement down to some reference and write it on the tool - could even get fancy and make up a height tool specific to setting the cutting tool elevation for your machine).

- Joined

- Dec 25, 2011

- Messages

- 10,503

Centers in spindle and tailstock and steel rule captured between them is an excellent quick method to determine in which direction the tailstock is off.

Quite a few companies (mostly Chinese of course) make a little gadget that is the quickest way to get a cutter on center. It has a leveling bubble on top. And a 90 deg V on what I will call the right end. And in line with and bisecting the 90, a flat surface under the bubble. To use, you press the V against a piece of round stock or tubing held in the chuck or collet. Rest the flat surface on top of the cutter and raise or lower the cutter until the bubble indicates level.

Quite a few companies (mostly Chinese of course) make a little gadget that is the quickest way to get a cutter on center. It has a leveling bubble on top. And a 90 deg V on what I will call the right end. And in line with and bisecting the 90, a flat surface under the bubble. To use, you press the V against a piece of round stock or tubing held in the chuck or collet. Rest the flat surface on top of the cutter and raise or lower the cutter until the bubble indicates level.

Next question is how to realign the tailstock after reassembly? I have not and will hot have the ability to accurately center drill anything to turn between centers to measure any taper, so how do I align the tailstock once I get it back together? It has always been aligned side to side (I've never had pieces come out tapered) but I assume it will be impossible for me to take it apart add shims and put it back together perfectly aligned...

- Joined

- Jan 16, 2015

- Messages

- 26

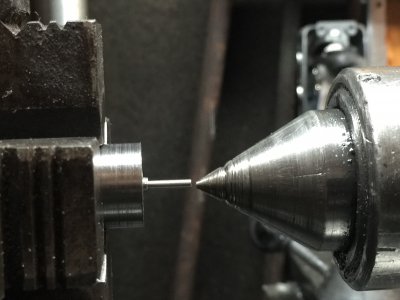

How far out of the tailstock is the quill in the picture? I've had tailstocks in the past that needed the lock snug to run right when more than an inch out. You may also want to check the taper on the quill, a taper reamer can do wonders for cleaning out burrs that drive you crazy. Setting side to side, after setting shims is fairly easy. It just takes patience. Many great YouTube videos on the subject.

How far out of the tailstock is the quill in the picture? I've had tailstocks in the past that needed the lock snug to run right when more than an inch out.

In the picture the tailstock is not extended at all. It is as far in as it can go without popping the live center out. As to tightening the lock down it does not change the position of the center.

One little burr in the tailstock taper can ruin your whole day/week/month.

I have never looked at the taper to see if it was messed up I will definitely check that out