-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

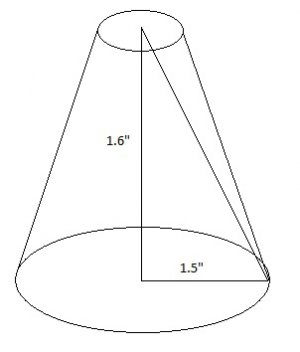

How to find the taper angle of a (sliced) cone

- Thread starter stioc

- Start date

- Joined

- Jun 7, 2013

- Messages

- 10,086

WHAT WOULD BE THE MATTER WITH USING A PROTRACTOR?

Ah! thanks. So the resulting number will be the large diameter? the height stays unchanged? e.g. say the small end is 1" the large end is 3" so 3-1=2 - I'll use 2 as the bottom diameter.Subtract the diameter of the small end from the large end now you have a point at the top

In other words: X=Inv Tan (Opposite/Adjacent)

X= Inv Tan (1.6/1)

X= 45deg

I could just do that but I felt I should use both methods to make sure I'm on the right track. More as an academic exercise than anything else.WHAT WOULD BE THE MATTER WITH USING A PROTRACTOR?

- Joined

- Nov 16, 2012

- Messages

- 5,596

You can't solve the problem as shown. You need to specify the small diameter too.

Let D be the big diameter and 'd' be the little diameter then R and r will be their radii respectively. Let H be the height of the cone.

R = D/2

r = d/2

Tan (angle) = (R-r)/H which means: angle = Arctan (R-r)/H

Ray

Let D be the big diameter and 'd' be the little diameter then R and r will be their radii respectively. Let H be the height of the cone.

R = D/2

r = d/2

Tan (angle) = (R-r)/H which means: angle = Arctan (R-r)/H

Ray

- Joined

- Nov 16, 2012

- Messages

- 5,596

If you want to know taper, that is normally expressed as inches per foot. The taper of a ramp in the example above would be R-r (in inches) divided by H (in feet). If you want the machine taper, you need to define if you want included angle or not. For included angle it would be D-d (in inches) divided by H (in feet). Check here and you'll see that different standards calculated taper differently (included vs non-included angle). I've encountered this confusion many times. https://en.wikipedia.org/wiki/Machine_taper

As far as the angle calculation in post #6, that is as fundamental as it gets -indisputable.

As far as the angle calculation in post #6, that is as fundamental as it gets -indisputable.

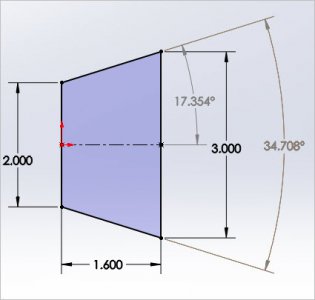

Not sure I understand your post-4 example, but here is a sketch with resultant dimensions. If your calculator spits out these angles, you are good to go.

Thanks Peter. I don't get those angles so I'm trying to figure out the correct math behind it.

You can't solve the problem as shown. You need to specify the small diameter too.

Let D be the big diameter and 'd' be the little diameter then R and r will be their radii respectively. Let H be the height of the cone.

R = D/2

r = d/2

Tan (angle) = (R-r)/H which means: angle = Arctan (R-r)/H

Ray

Thanks Ray- I believe that's exactly how I calculated it but I'm not getting the correct angles. If you want to try it:

D=3

d=2

EDIT: OOPS! you're right! I think in my second post example I didn't use the correct numbers. This is right, YAY! lol

Arctan (1.5-1)/1.6=17.35 deg

Thanks guys!

Last edited:

- Joined

- Nov 16, 2012

- Messages

- 5,596

3/2 = 1.5

2/2 = 1

1.5 - 1 = 0.5/1.6

arctan 0.5/1.6 =17.35 Measured from centerline of cone.

EDITED to show the calculations. I also had to edit this because I can't see a darn thing w/o my glasses using a browser on a mobile phone.

2/2 = 1

1.5 - 1 = 0.5/1.6

arctan 0.5/1.6 =17.35 Measured from centerline of cone.

EDITED to show the calculations. I also had to edit this because I can't see a darn thing w/o my glasses using a browser on a mobile phone.

Last edited: