- Joined

- Oct 10, 2018

- Messages

- 543

Hi:

I'm a brand-new newbie with a little Atlas 618. For the past few days, I've been trying various things to get a decent cut on some random scraps of steel. I've just ground a HSS tool bit from scratch but the finish still isn't smooth:

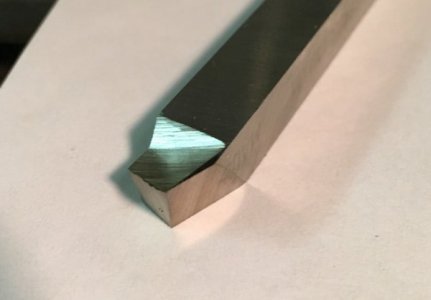

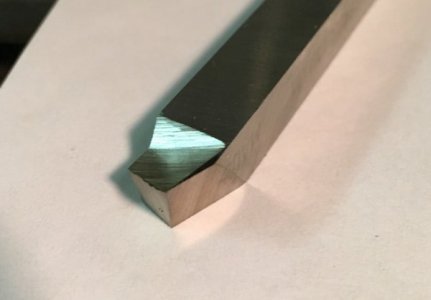

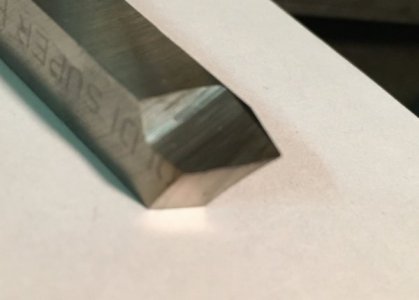

The part is about 1/2" diameter and the lathe is set at 540 rpm. I'm using the power feed and I believe I'm on the slowest feed rate--need to verify. I tried to follow recommendations from 'mikey' in another thread and ground the bit with 15 degree angles for side relief, end relief and back rake. Used a coarse wheel on a 6-inch 3400 rpm grinder. Following is the bit _before_ honing:

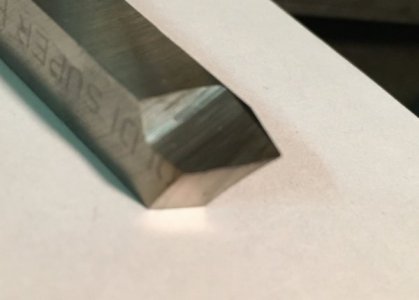

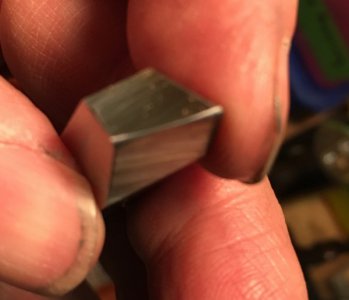

I used a diamond plate to add the radius and a fine sharpening stone to polish all the cutting edges. Hard to get a good picture but the bit looked kinda like this after honing:

I have considerable experience with sharpening woodworking tools and I feel I got a good polished edge on each of the surfaces that come together at the cutting point.

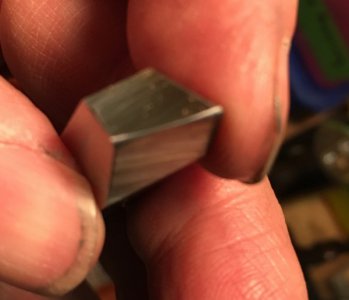

If it helps, this is what the tool looked like in the lathe:

And these are the chips produced:

Hope somebody can get me on the right track.

Thanks,

Craig

I'm a brand-new newbie with a little Atlas 618. For the past few days, I've been trying various things to get a decent cut on some random scraps of steel. I've just ground a HSS tool bit from scratch but the finish still isn't smooth:

The part is about 1/2" diameter and the lathe is set at 540 rpm. I'm using the power feed and I believe I'm on the slowest feed rate--need to verify. I tried to follow recommendations from 'mikey' in another thread and ground the bit with 15 degree angles for side relief, end relief and back rake. Used a coarse wheel on a 6-inch 3400 rpm grinder. Following is the bit _before_ honing:

I used a diamond plate to add the radius and a fine sharpening stone to polish all the cutting edges. Hard to get a good picture but the bit looked kinda like this after honing:

I have considerable experience with sharpening woodworking tools and I feel I got a good polished edge on each of the surfaces that come together at the cutting point.

If it helps, this is what the tool looked like in the lathe:

And these are the chips produced:

Hope somebody can get me on the right track.

Thanks,

Craig