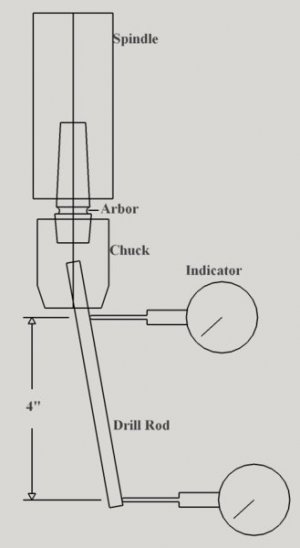

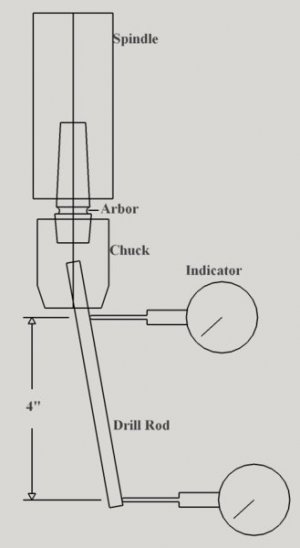

I would like to reduce the runout of my drill press. I've made about 50 measurements, and have determined that most of my runout is in the chuck, and that most of my problem is with repeatability of chucking the drill rod. See attached sketch which depicts the problem (exaggerated). I measured TIR on the drill rod at a location just below the chuck and again 4 inches below the chuck. The TIR measurement was repeatedly made at these 2 locations while I re-indexed 1) the arbor in the spindle, 2) the chuck on the arbor, or 3) the drill rod in the chuck. The high spot always follows the chuck. TIR near the chuck ranged from 0.0005-0.0045" with 0.0025" being typical. TIR '4 inches down' ranged from 0.003-0.014" with 0.009" being typical. I don't think this is really all that bad, and I can get acceptable results by just matching high spots to low spots. I am however considering purchasing a new chuck with less runout and hopefully more repeatability. All of this is just background to frame my question. It's not really important to my question, but I figure that someone will ask for more info.

My question:

The makers and sellers of chucks will advertise maximum TIR. What exactly are they claiming to be within the spec? For example: Shar's model 202-4968, "High Precision Heavy Duty Keyless Drill Chuck" claims TIR of 0.002". If I bought one and measured a repeatable TIR of 0.002" near the drill chuck, and TIR of 0.010" at '4 inches down', I would be disappointed, but would it be 'Out of Spec'? In other words, is the maximum TIR (for the purpose of comparing it to the spec) to be measured on the drill rod, near the chuck or somewhere else?

My question:

The makers and sellers of chucks will advertise maximum TIR. What exactly are they claiming to be within the spec? For example: Shar's model 202-4968, "High Precision Heavy Duty Keyless Drill Chuck" claims TIR of 0.002". If I bought one and measured a repeatable TIR of 0.002" near the drill chuck, and TIR of 0.010" at '4 inches down', I would be disappointed, but would it be 'Out of Spec'? In other words, is the maximum TIR (for the purpose of comparing it to the spec) to be measured on the drill rod, near the chuck or somewhere else?