That can be a symptom of a non-functioning unloader valve. Take the cover off the switch and watch the operation of the valve, make sure the pin is being pressed down when the switch shuts off. It's possible it got tweaked when you tightened the air line fittings. If it was work fine before you changed the switch that would be the first thing to check.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to repair compressor pressure switch?

- Thread starter Janderso

- Start date

- Joined

- Feb 2, 2013

- Messages

- 3,622

i'd check the pressure switch operation to make sure the contact is being made there.

the pressure should bleed off every time the compressor stops

the pressure should bleed off every time the compressor stops

- Joined

- Jul 2, 2014

- Messages

- 7,594

That is so the motor and compressor can start turning from stopped without a load on them. Motors do not like to start under a heavy load. That is what the air line bleed down function on shutdown is for.the pressure should bleed off every time the compressor stops

- Joined

- Feb 1, 2015

- Messages

- 9,574

I installed a small reservoir between the pump and the check valve on my homebuilt to give the motor a better chance of coming to speed before it was loaded. The reservoir volume was similar to the displacement of the pump so it would take several revolutions of the pump to load the pump.

Things to check:

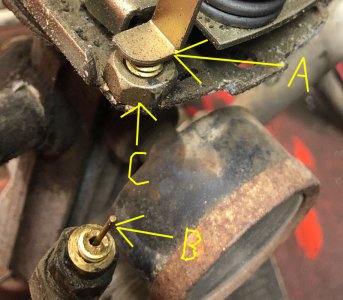

When the compressor shuts off lever A should press down firmly on pin B. This bleeds the air out of the cylinder to allow restarting with no load on the piston.

Check nut C and make sure it didn't come loose when you attached the air line. If it gets loose the valve will not open.

If air comes out of this valve for more than about 5 seconds after the compressor shuts off, then your check valve ( usually located where the air line from the cylinder head enters the tank) is leaking. These can often be removed and cleaned and will work again.

- Joined

- Mar 26, 2018

- Messages

- 8,397

It’s definitely the valve. I really gronked down on the plastic line fittings, probably screwed up.

It makes sense, the flywheel is way too stiff. I have pressure built up. Now I know why the motor buzzes-won’t start.

It’s 5 hp.

Thanks, I’ll check it out tonight.

It makes sense, the flywheel is way too stiff. I have pressure built up. Now I know why the motor buzzes-won’t start.

It’s 5 hp.

Thanks, I’ll check it out tonight.

- Joined

- Mar 26, 2018

- Messages

- 8,397

OK, I replaced the valve, no change.

The little hole on the side of the valve where the short term release of pressure is released (when the maximum pressure is achieved) just continues to bleed off pressure. When the low pressure starts the motor it just hums because the flywheel is locked due to pressure.

Is there a check valve somewhere that may be inoperative?

Why does the new valve bleed off the whole time?

I'm about ready to go buy a new IR 2 stage, 5HP, 60 gallon tank, 230v single phase. Talk me out of it please.

The little hole on the side of the valve where the short term release of pressure is released (when the maximum pressure is achieved) just continues to bleed off pressure. When the low pressure starts the motor it just hums because the flywheel is locked due to pressure.

Is there a check valve somewhere that may be inoperative?

Why does the new valve bleed off the whole time?

I'm about ready to go buy a new IR 2 stage, 5HP, 60 gallon tank, 230v single phase. Talk me out of it please.