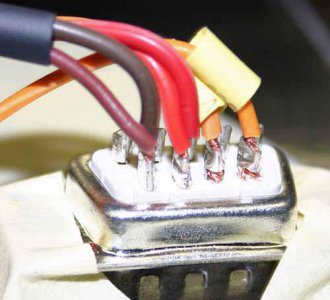

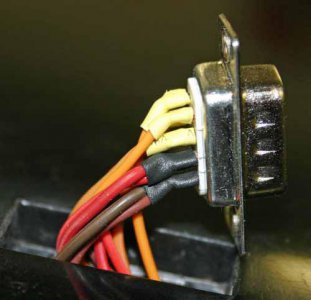

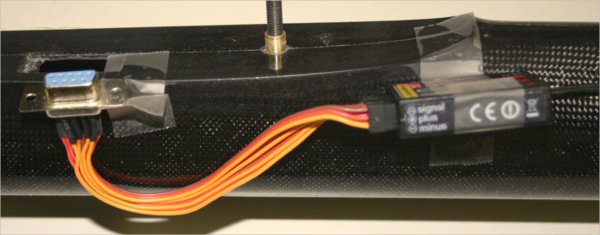

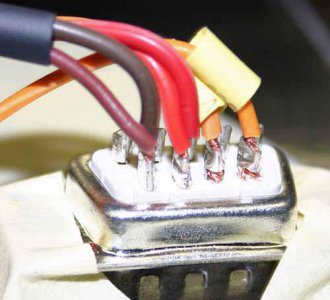

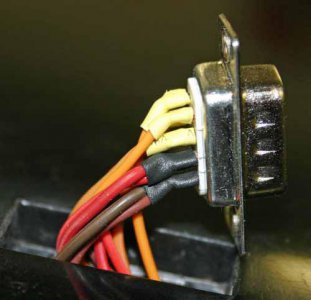

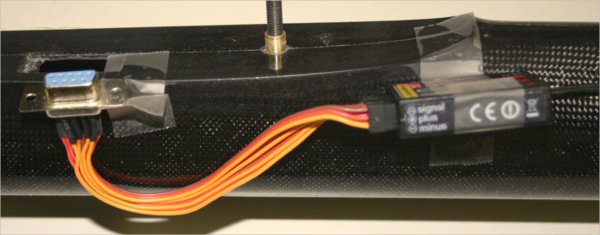

One of my other hobbies is RC airplanes. The electric models demand some fickle soldering now & again. This is an electric sailplane with a DB9 plug & wiring harness that connects the 4 wing servo leads back to the receiver in located in the fuselage. Some of the wires are doubled up on common pins which is a PITA. Soldering is the normal/preferred mode but actually when the wires are cramped & constrained, this can be a liability because now the joint is hard (= break failure point).

I bought some pure silver rings which come in all sizes and a teeny plier crimp tool. This stuff is used by the jewelry bead hobbyists & very inexpensive. It was crimped & completed before the solder iron would have been warm. Actually all RC plugs are crimped inside their male/female housing. Its a lot more common in industry than I realized. Just mentioning to keep in your bag of electrical tricks.

I bought some pure silver rings which come in all sizes and a teeny plier crimp tool. This stuff is used by the jewelry bead hobbyists & very inexpensive. It was crimped & completed before the solder iron would have been warm. Actually all RC plugs are crimped inside their male/female housing. Its a lot more common in industry than I realized. Just mentioning to keep in your bag of electrical tricks.

Last edited: