- Joined

- Dec 18, 2019

- Messages

- 6,437

Offbeat question. Background. Laptop died. (Power supply on MB.) Waiting for new laptop to arrive... Don't even have an estimated time of arrival. Temporarily using a Raspberry Pi 4 (RPi4) as a primary computer. Once I was able to boot from SSD, it isn't too bad.

Problem is 1) limited number of ports on the RPi4, 2) spacing of ports on the RPi4, and 3) USB male connectors don't seem to have a standard height for the plastic overmold.

Basically, the adapter I need to use has a non-standard thicker connector. We are not talking super thick, but thick enough to interfere with the connector below. So thinking out loud here... All I need to do is mill off a little from the plastic connector, until I get a fit.

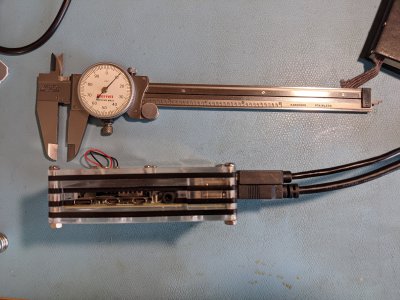

The stacked connector spacing on the RPi4 I measure to be 8mm, or 0.315". I have 2 cables which measure 0.370 and 0.331. The thicker one is attached to a USB3 to SATA adapter, that's my SSD. The other is for a small unpowered USB3 hub.

How could one hold the male connectors tight enough to mill? Other things to watch out for? I do have a fallback for the disk. Have an external disk housing that I can pop the disk into an run. It's slower than the plug in adapter, but workable.

Problem is 1) limited number of ports on the RPi4, 2) spacing of ports on the RPi4, and 3) USB male connectors don't seem to have a standard height for the plastic overmold.

Basically, the adapter I need to use has a non-standard thicker connector. We are not talking super thick, but thick enough to interfere with the connector below. So thinking out loud here... All I need to do is mill off a little from the plastic connector, until I get a fit.

The stacked connector spacing on the RPi4 I measure to be 8mm, or 0.315". I have 2 cables which measure 0.370 and 0.331. The thicker one is attached to a USB3 to SATA adapter, that's my SSD. The other is for a small unpowered USB3 hub.

How could one hold the male connectors tight enough to mill? Other things to watch out for? I do have a fallback for the disk. Have an external disk housing that I can pop the disk into an run. It's slower than the plug in adapter, but workable.