- Joined

- May 3, 2017

- Messages

- 1,997

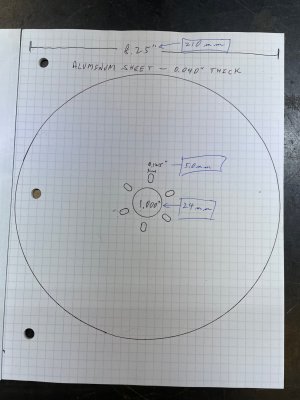

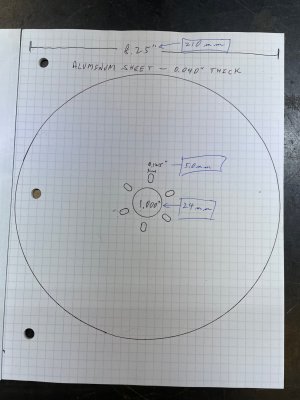

I'm trying to visualize the most efficient way to make the part in the drawing attached below. I'll need to make several, so the closer I can get to assembly-lining the process, the better. Accurate measurements are more likely the metric values.

I'm thinking something along these lines:

1. Make a sacrificial plate that's slightly smaller than the overall diameter - 7-3/4" - 8" or so. I have a piece of 3/8" aluminum that will work perfectly.

2. Mill a hole in the center of the plate to accommodate the center hole and the six slotted holes.

3. Center-mount the plate and a slightly over-sized blank onto my 12" rotary table, clamping on all four slots.

4. Mill the interior hole and slots. The slots are actually on two-alternating diameters. It would be simple to determine the diameters and make alternating internal and external holes, but the slots would probably easier.

5. Move to the outside diameter and mill by removing and replacing one clamp at a time.

Any feedback or suggestions for a better approach?

Thanks in advance.

Regards

I'm thinking something along these lines:

1. Make a sacrificial plate that's slightly smaller than the overall diameter - 7-3/4" - 8" or so. I have a piece of 3/8" aluminum that will work perfectly.

2. Mill a hole in the center of the plate to accommodate the center hole and the six slotted holes.

3. Center-mount the plate and a slightly over-sized blank onto my 12" rotary table, clamping on all four slots.

4. Mill the interior hole and slots. The slots are actually on two-alternating diameters. It would be simple to determine the diameters and make alternating internal and external holes, but the slots would probably easier.

5. Move to the outside diameter and mill by removing and replacing one clamp at a time.

Any feedback or suggestions for a better approach?

Thanks in advance.

Regards