- Joined

- Oct 16, 2017

- Messages

- 338

This post will document the method I used to reduce the striker spring tension in a Howa 6.5 Creedmoor bolt. This method is applicable to other Howa/Weatherby Vanguard actions. The rifle shown below is my go-to 6.5 Creedmoor for PRS matches. My only complaint was the force required to lift the bolt (e.g. cocking) was very high; to the point where it was difficult to stay on target during a follow up shot.

Step 1. Measure the position of the *Cocking Piece relative to the rear of the *Bolt Sleeve Body in the fired and cocked position. These measurements will be used when calculating the amount of spring removal. (*I will use bolt component nomenclature per Frank de Haas, "Bolt Action Rifles, 3rd Edition", page 469).

With the striker in the fired position I measured 0.345" from the Cocking Piece to the Bolt Sleeve Body.

With the striker in the cocked position I measured 0.055" from Cocking Piece to the Bolt Sleeve Body.

Based on these measurements the striker travels ~0.400" from cocked to fired.

Step 2. Remove the bolt and remove the striker assembly from the bolt by twisting the rear of the Bolt Sleeve Body clockwise. Note: the picture below was taken after the spring was shortened.

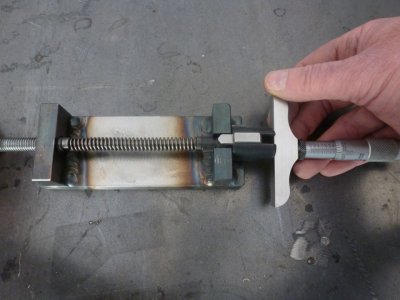

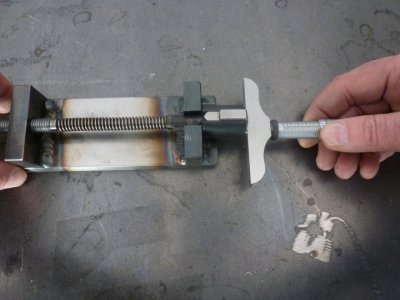

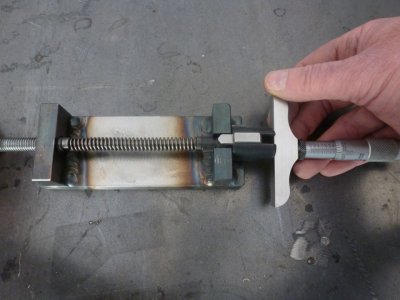

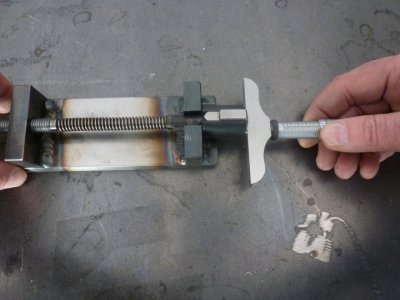

Step 3. Prepare a spring compression jig similar to mine shown below. My jig is over-built because I used available scrap. The threaded rod is drilled to swallow the pin end of the striker. The notch is machined to capture the striker against the small lug. When the striker assembly is compressed, spring compression is relieved from the Cocking Piece. There are alternate methods to using a jig but these can result in damage to the striker assembly. I have dealt with Legacy Sports (Howa importer to the US) with questions about replacement parts and they are zero help.

Step 4. Compress the striker assembly until Cocking Piece is in the fired position as measured in Step 1.

Measure and record the Striker Spring length. I measure 3.24".

Step 5. Compress the striker assembly until Cocking Piece is in the cocked position as measured in Step 1.

Measure and record the Striker Spring length. I measured 2.84".

Step 6. Compress the striker until the Cocking Piece Retaining Pin is exposed. The retaining pin is solid with staking splines on one end.

Drive the pin out from the end opposite the staking splines. If you drive the from the spline end you may shear the splines.

Below shows all pieces of the striker assembly. Measure and record the length of the uncompressed spring. I measure 4.38".

Step 7. Estimate the spring constant (K) by applying a force to the spring and measuring the displacement. For my crude method I held the striker in the vice, measured the distance from the end of the striker to a plastic washer before and after compression using plates from my weight set. Not super accurate but it got me in the ball park.

Step 8. Calculate the spring constant K and the length of spring to remove using Hooke's Law (F = KX) at the desired reduction of spring force.

I decided to reduce bolt lift force by one half. That would require shooting for a spring force of 20.5 lbf / 2 = ~10 lbf with the striker in the cocked position.

The final uncompressed spring length resulting in 10 lbf with the striker in the cocked position was obtained by solving for L: 13.3 lbf/in X (L - 2.84") = 10 lbf.

Solving for L gives a final uncompressed spring length of 3.60".

With the new uncompressed spring length I calculated the spring compression before I cut.

Step 9. Cut the spring using an angle grinder with a cut off wheel. You cannot cut this spring with side cutters.

Step 9. Reassemble the bolt and test fire using primed only brass. I cut the spring to final length in three stages, assembling and testing after each cut and am very happy with the final result. Now maybe I can stay on target for that follow up shot.

Step 1. Measure the position of the *Cocking Piece relative to the rear of the *Bolt Sleeve Body in the fired and cocked position. These measurements will be used when calculating the amount of spring removal. (*I will use bolt component nomenclature per Frank de Haas, "Bolt Action Rifles, 3rd Edition", page 469).

With the striker in the fired position I measured 0.345" from the Cocking Piece to the Bolt Sleeve Body.

With the striker in the cocked position I measured 0.055" from Cocking Piece to the Bolt Sleeve Body.

Based on these measurements the striker travels ~0.400" from cocked to fired.

Step 2. Remove the bolt and remove the striker assembly from the bolt by twisting the rear of the Bolt Sleeve Body clockwise. Note: the picture below was taken after the spring was shortened.

Step 3. Prepare a spring compression jig similar to mine shown below. My jig is over-built because I used available scrap. The threaded rod is drilled to swallow the pin end of the striker. The notch is machined to capture the striker against the small lug. When the striker assembly is compressed, spring compression is relieved from the Cocking Piece. There are alternate methods to using a jig but these can result in damage to the striker assembly. I have dealt with Legacy Sports (Howa importer to the US) with questions about replacement parts and they are zero help.

Step 4. Compress the striker assembly until Cocking Piece is in the fired position as measured in Step 1.

Measure and record the Striker Spring length. I measure 3.24".

Step 5. Compress the striker assembly until Cocking Piece is in the cocked position as measured in Step 1.

Measure and record the Striker Spring length. I measured 2.84".

Step 6. Compress the striker until the Cocking Piece Retaining Pin is exposed. The retaining pin is solid with staking splines on one end.

Drive the pin out from the end opposite the staking splines. If you drive the from the spline end you may shear the splines.

Below shows all pieces of the striker assembly. Measure and record the length of the uncompressed spring. I measure 4.38".

Step 7. Estimate the spring constant (K) by applying a force to the spring and measuring the displacement. For my crude method I held the striker in the vice, measured the distance from the end of the striker to a plastic washer before and after compression using plates from my weight set. Not super accurate but it got me in the ball park.

Step 8. Calculate the spring constant K and the length of spring to remove using Hooke's Law (F = KX) at the desired reduction of spring force.

- It took ~15 lbf to compress the spring ~1-1/8": K = 15 / 1.125 or K = ~13.3 lbf/in

- When the striker is in the cocked position, the spring force is 13.3 lbf/in X (4.38" - 2.84") = 20.5 lbf

- When the striker is in the fired position, the spring force is 13.3 lbf/in X (4.38" - 3.24") = 15.2 lbf

I decided to reduce bolt lift force by one half. That would require shooting for a spring force of 20.5 lbf / 2 = ~10 lbf with the striker in the cocked position.

The final uncompressed spring length resulting in 10 lbf with the striker in the cocked position was obtained by solving for L: 13.3 lbf/in X (L - 2.84") = 10 lbf.

Solving for L gives a final uncompressed spring length of 3.60".

With the new uncompressed spring length I calculated the spring compression before I cut.

- When the striker is in the cocked position, the spring force is 13.3 lbf/in X (3.60" - 2.84") = ~10.1 lbf.

- When the striker is in the fired position, the spring force is 13.3 lbf/in X (3.60" - 3.24") = ~4.8 lbf.

Step 9. Cut the spring using an angle grinder with a cut off wheel. You cannot cut this spring with side cutters.

Step 9. Reassemble the bolt and test fire using primed only brass. I cut the spring to final length in three stages, assembling and testing after each cut and am very happy with the final result. Now maybe I can stay on target for that follow up shot.

Last edited: