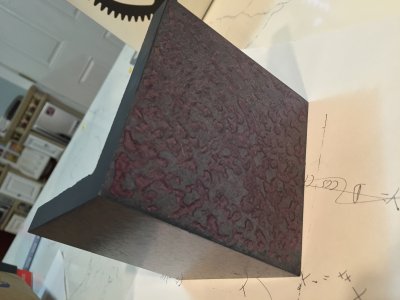

OK, so I bought a camelback straight edge casting that popped up on craigslist. So I figured if I wanted to scrape it I should start learning on something less nice. So I bought this 15 dollar cast iron knee from enco and have been attempting to teach myself to scrape it in. Could someone offer feedback on the progress? I watched rich's scraping dvd and whatever I could find on youtube and kind of just went for it.