A

Andre

Forum Guest

Register Today

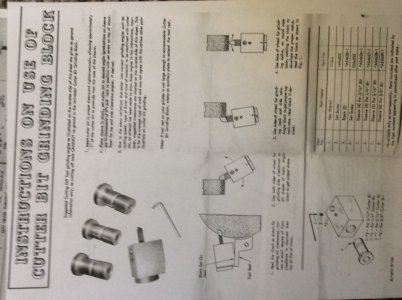

Could you post a picture of it?The first tool I made as an apprentice (back in 1972) was a fixture to hold 3/8 lathe bits for grinding a threading tool, but it needs a surface grinder to do the grinding. I don't have one, (surface grinder) so my fixture is useless to me.

)

)