Hi Clockman44,

Yes you must remove the end bearing and then free the leadscrew from the gearbox end. There should be a tapered pin in the gearbox shaft or the leadscrew somewhere near the gearbox. Sometimes these blend into the shaft and are difficult to recognize. You must remove it by tapping it out from the small side of the taper. Be careful to determine for sure which side of the pin is the small side.

If it is not threaded, it will come out of the leadscrew by closing the half-nuts and carefully moving the carriage until it is free. If it is threaded into the gearbox shaft, you will need to find a non-marring way to free it, using the non-threaded end of the leadscrew. I have never seen one that was threaded so if you have one please post some pics when you have it out.

Once the leadscrew is free, try to avoid the temptation to pull it out of the apron. That is the only thing holding the worm in and there is a lubrication tube for the worm that could be damaged if you do that. Keep the half-nuts closed until you reach the bench and have a chance to observe what's there before releasing it. I hope this helps.

Below is an image of a typical Sheldon leadscrew notice the pin-hole in the shaft at the gearbox end.

View attachment 302806

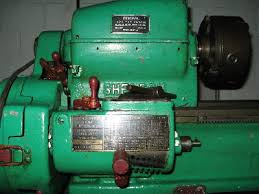

The gearbox below looks like mine. My leadscrew has a bore at the end and the pin goes through the leadscrew and the gearbox shaft end.

View attachment 302808

Best Regards,

Bob