-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I have made the decision to CNC it!

- Thread starter OakRidgeGuy

- Start date

- Joined

- Oct 6, 2012

- Messages

- 486

I looked at the tutorial for this, but it is not sinking it.. haha! I will have it..

- Joined

- Oct 6, 2012

- Messages

- 486

I missed that post where you found the ogive. I will need to do that to get my chucking reamers made in the future.. they have to be a specific curve. 9 degree or 7 degree, depending on whether it is a secant or tangent ogive.

This was a bit back in the thread, but hey, I am catching up.

Regarding pendants, you don't really need one, you can use the keyboard to jog (arrow keys, page up/down). If you want a cheap pendant, LinuxCNC (and I believe Mach) can use inexpensive USB game pads as pendants. I have not set one up yet, so I don't know the level of difficulty, but it's something to keep in mind.

DMS

Regarding pendants, you don't really need one, you can use the keyboard to jog (arrow keys, page up/down). If you want a cheap pendant, LinuxCNC (and I believe Mach) can use inexpensive USB game pads as pendants. I have not set one up yet, so I don't know the level of difficulty, but it's something to keep in mind.

DMS

- Joined

- Jul 7, 2012

- Messages

- 641

This was a bit back in the thread, but hey, I am catching up.

Regarding pendants, you don't really need one, you can use the keyboard to jog (arrow keys, page up/down). If you want a cheap pendant, LinuxCNC (and I believe Mach) can use inexpensive USB game pads as pendants. I have not set one up yet, so I don't know the level of difficulty, but it's something to keep in mind.

DMS

You can, but a pendant is a little more ergonomic than a keyboard. You can use game pads and similar items as well, but the $32 pendant Jumps showed is specifically designed for Mach3 (no boards or add ons are needed), and it has more functions available than a game pad and they're all labeled.

There are more expensive ones available (just check eBay) and they appear to be of significantly higher quality construction and IMO are more appealing to the eye; but for $32 the one discussed is a great value and it appears to do the job.

M

- Joined

- Oct 6, 2012

- Messages

- 486

When I get ready for one, I will get one, I have not decided yet as to which one I will get. I did look at a few others.

http://www.vistacnc.com/index.htm

http://www.vistacnc.com/index.htm

- Joined

- Oct 6, 2012

- Messages

- 486

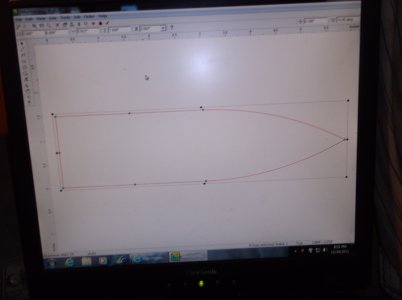

Still having problems with the arc

- Joined

- Oct 6, 2012

- Messages

- 486

Steve,

Actually, in the first photo that I posted. Look at the bottom right of the post, I want to draw an arc from about .05 from the front and up arcing to the back about .010 below the tansverse hole. And then removing that material down to .110. and then repeat the same thing on the other side. This would leave an arc with a angled brace going through the arc.. have I made myself clear enough?

Doc

Actually, in the first photo that I posted. Look at the bottom right of the post, I want to draw an arc from about .05 from the front and up arcing to the back about .010 below the tansverse hole. And then removing that material down to .110. and then repeat the same thing on the other side. This would leave an arc with a angled brace going through the arc.. have I made myself clear enough?

Doc