- Joined

- Mar 17, 2018

- Messages

- 1,400

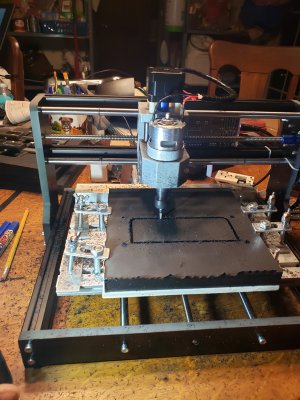

I am going to have so many questions. Fortunately my son is a professional CNC programmer and machinist. He was here until 1:30 am last night to get me started and had to get up at 6 am for work today. I am so grateful to have him! He left his very powerful laptop here for me to run my machine.

My question for tonight is, can I take the memory stick out of his computer while the program is running? I don't think its using the stick to run it, but I'm not sure.

Earlier today his computer went to sleep and the router stopped in the middle of a part. I just had to change a setting on his computer.

Thanks in advance.

There will be many more questions!

I look at this as getting my feet wet before I get a real CNC machine.

My question for tonight is, can I take the memory stick out of his computer while the program is running? I don't think its using the stick to run it, but I'm not sure.

Earlier today his computer went to sleep and the router stopped in the middle of a part. I just had to change a setting on his computer.

Thanks in advance.

There will be many more questions!

I look at this as getting my feet wet before I get a real CNC machine.