- Joined

- Jan 20, 2016

- Messages

- 602

I have been working on a chess set for my dad for Christmas and I needed a 55 degree insert holder to do the bishops. I gave him the kings, queens, rooks, and pawns already on Christmas, now I just need to finish the bishops and knights. For that, I wanted to use CNC.

Anyway, the holders are made from 1/2" aluminum plate and the measure .375x.375x2.5" once complete. I made them using my converted X2 CNC mill. The screw is a 4-40 cap screw and the insert is a DCMT070202. I used fusion 360 to model it, then it was a quick 5 operations. Rough with 3/8" end mill, finish with 1/8" end mill, center drill, through drill, tap, then flip and face off the other end. They took about 20 minutes each to do and I tested one cutting aluminum and I was pleased with its performance.

Here is the pair of insert holders.

Here is a slightly closer look at one of them.

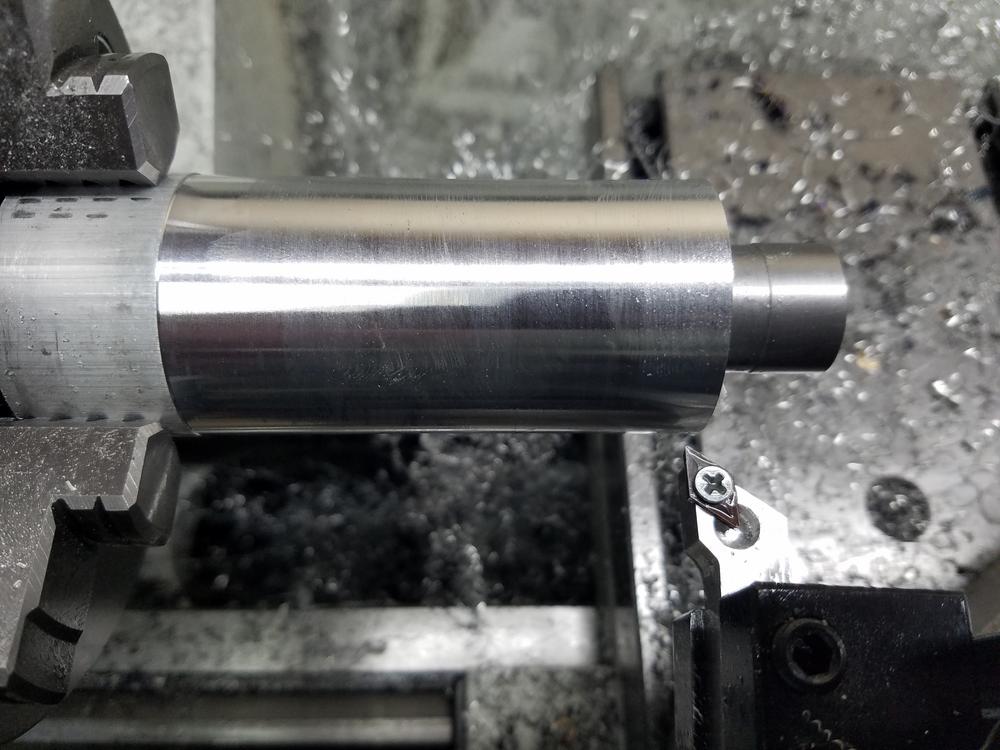

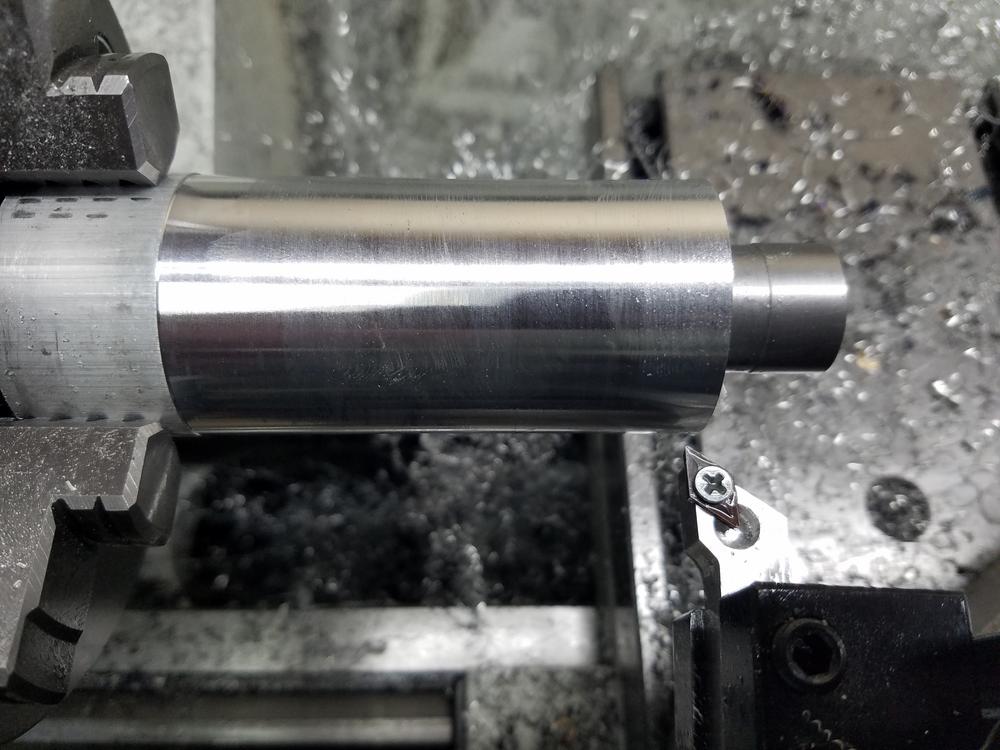

Here is the finish it left on a piece of 6061 aluminum. I didn't push it, but at .01", it was cutting fine and leaving a nice finish.

Anyway, the holders are made from 1/2" aluminum plate and the measure .375x.375x2.5" once complete. I made them using my converted X2 CNC mill. The screw is a 4-40 cap screw and the insert is a DCMT070202. I used fusion 360 to model it, then it was a quick 5 operations. Rough with 3/8" end mill, finish with 1/8" end mill, center drill, through drill, tap, then flip and face off the other end. They took about 20 minutes each to do and I tested one cutting aluminum and I was pleased with its performance.

Here is the pair of insert holders.

Here is a slightly closer look at one of them.

Here is the finish it left on a piece of 6061 aluminum. I didn't push it, but at .01", it was cutting fine and leaving a nice finish.