- Joined

- Aug 13, 2020

- Messages

- 1,342

Craftsman Commercial 12x36 one day started trying to walk the floor if I tried to go above 1,000 rpm.

I've been living with it by keeping it slow, but recently found a claim that different length belts would cause this problem.

I checked, and sure enough, one of the belts was tight while the other had several inches of play.

The loose belt sit deeper in the groove of both the top and bottom spindle.

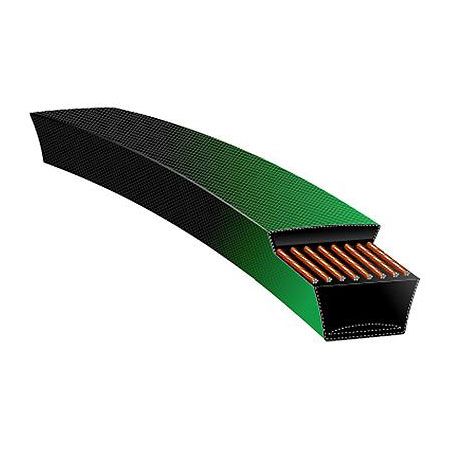

The printing on the tight belt is clear. "4L540 Goodyear FHP". The printing on the other is barely legible, but I think it is the same.

I'm not able to measure the V grooves, but the belts measure the same width and thickness.

My lathe was modified by a PO so that the 1Hp motor drives the spindle directly, and it appears that the weight of the motor may be used for tension.

So now for the guessing what happened.

I'm going to go with the loose belt was slipping all along. There was a slight difference in diameters of the pulleys initially, but over time the grooves for the loose belt have been ground down. . . resulting in it sitting deeper in the grooves. . . resulting in more slippage, then more wear. This also caused the belt to heat up and oxidize the printing on it. These belts are AT LEAST 12 years old.

The fix?

Swapping belts is a PIA, but I'm up for that.

Is there a better belt selection than this Goodyear? Rotate the spindle by hand, and they sound like wet sneakers on a basketball court.

Does it make sense to replace the belts if the Vs are damaged? How can I tell if the pulley Vs are damaged?

I've been living with it by keeping it slow, but recently found a claim that different length belts would cause this problem.

I checked, and sure enough, one of the belts was tight while the other had several inches of play.

The loose belt sit deeper in the groove of both the top and bottom spindle.

The printing on the tight belt is clear. "4L540 Goodyear FHP". The printing on the other is barely legible, but I think it is the same.

I'm not able to measure the V grooves, but the belts measure the same width and thickness.

My lathe was modified by a PO so that the 1Hp motor drives the spindle directly, and it appears that the weight of the motor may be used for tension.

So now for the guessing what happened.

I'm going to go with the loose belt was slipping all along. There was a slight difference in diameters of the pulleys initially, but over time the grooves for the loose belt have been ground down. . . resulting in it sitting deeper in the grooves. . . resulting in more slippage, then more wear. This also caused the belt to heat up and oxidize the printing on it. These belts are AT LEAST 12 years old.

The fix?

Swapping belts is a PIA, but I'm up for that.

Is there a better belt selection than this Goodyear? Rotate the spindle by hand, and they sound like wet sneakers on a basketball court.

Does it make sense to replace the belts if the Vs are damaged? How can I tell if the pulley Vs are damaged?