-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I ordered a PM-940M-PDF

- Thread starter Dan_S

- Start date

- Joined

- Aug 26, 2013

- Messages

- 1,061

Last night I started cleaning off all the shipping grease. Most of it went quickly, but getting the black goop out of the table t slots was kind of a pain. Mineral spirits wasn't really cutting it, so I had to break out the nasty stuff. Naptha and a role of paper towels took care of it fairly quickly.

Matt has a new head up/down motor in the mail to me, and I can't wait to get it, because the head is damn heavy. I had to crank it up and down through it full range a few times last night while cleaning, and it was a real workout. I picked up some fasteners over lunch, to replace some of the stock ones that I didn't like.

I've also determined that the front y axis way cover needs to be trimmed some. It's nice that it protects the ways when the y is all the way back, but it's going to get in the way and be a nuisance during normal use.

Matt has a new head up/down motor in the mail to me, and I can't wait to get it, because the head is damn heavy. I had to crank it up and down through it full range a few times last night while cleaning, and it was a real workout. I picked up some fasteners over lunch, to replace some of the stock ones that I didn't like.

I've also determined that the front y axis way cover needs to be trimmed some. It's nice that it protects the ways when the y is all the way back, but it's going to get in the way and be a nuisance during normal use.

- Joined

- Aug 26, 2013

- Messages

- 1,061

Hopefully I'll actually get a chance to use the mill tonight, now that it's set up an trammed & toned. Everything on the mill was within half a thousands across several inches of travel.

As a side note the quill has 5-1/4" of travel, not 5 as quoted.

Some modifications I've made already, are shown below.

I switched the long hex head bolts that hold the power-feed on, to shorter socket head cap screws. This should make it less likely I cut my self on the bolt heads, and give me a little more room to get t nuts on and off the machine.

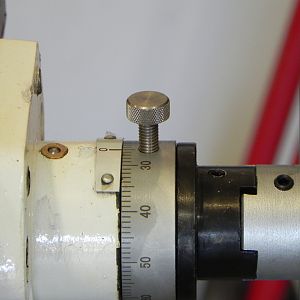

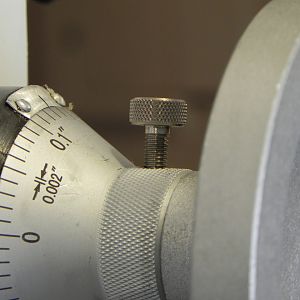

I switched the thumb screws on the x, y and quill over to some stainless ones that have a better knurl pattern (imo).

the x-axis

the quill

As a side note the quill has 5-1/4" of travel, not 5 as quoted.

Some modifications I've made already, are shown below.

I switched the long hex head bolts that hold the power-feed on, to shorter socket head cap screws. This should make it less likely I cut my self on the bolt heads, and give me a little more room to get t nuts on and off the machine.

I switched the thumb screws on the x, y and quill over to some stainless ones that have a better knurl pattern (imo).

the x-axis

the quill

- Joined

- Mar 21, 2013

- Messages

- 4,063

Not bad Dan, for a young guy (sorry...I couldn't resist)

I am surprised that you didn't put machine leveling feet on the base though. It would have helped with that uneven stance/vibrating.

I don't know how tall you are, but that machine is sitting way too close to the ground for me. My table sits at ~44" off the ground and well above my waist when I'm in front of it. But then I'm 6'3" and too old to stoop for very long. I'm sure you'll do fine.

I am surprised that you didn't put machine leveling feet on the base though. It would have helped with that uneven stance/vibrating.

I don't know how tall you are, but that machine is sitting way too close to the ground for me. My table sits at ~44" off the ground and well above my waist when I'm in front of it. But then I'm 6'3" and too old to stoop for very long. I'm sure you'll do fine.

- Joined

- Aug 26, 2013

- Messages

- 1,061

Lol, I bet I'm older than you think I am.Not bad Dan, for a young guy (sorry...I couldn't resist)

I am surprised that you didn't put machine leveling feet on the base though. It would have helped with that uneven stance/vibrating.

I don't know how tall you are, but that machine is sitting way too close to the ground for me. My table sits at ~44" off the ground and well above my waist when I'm in front of it. But then I'm 6'3" and too old to stoop for very long. I'm sure you'll do fine.

That's what I've been working on this week, I got all the machining done last night, and hopefully I'll get welding done today. The base I'm building will lift the mill at least 6", and put the table at roughly 42", as well as a provide a way to level the mill and get a rock solid footing.

- Joined

- Aug 26, 2013

- Messages

- 1,061

I got all the welding done tonight, except welding the threaded plugs in place. My MIG welds are never going to be as pretty as some iv'e seen, but considering I don't do it very often and I have a cheap no name 110 machine I think this one turned out pretty well.

It's the root pass on a 3 inch wide butt joint.

It's the root pass on a 3 inch wide butt joint.