- Joined

- Dec 18, 2013

- Messages

- 87

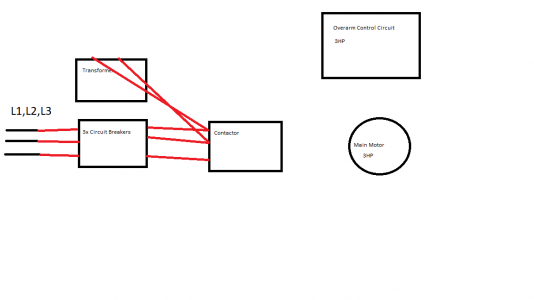

I am leaning toward just replacing everything as it has been hacked on for who knows how long and I believe all the protections have been taken out.If it was me I'd just replace the contactor, overload heater, switches, and transformer. Rewire the whole thing in the process. You have old heat damaged components, corroded terminals, and jumpered heaters. It'll cost you a bit of money, but if you have some feel for electronics it is relatively easy.

So the only question is with two motors ... do both motors run at the same time? Or is the photos shown of only one motor's control circuitry? *Ideally* the two motors would each have their own overload heater, set for their Full Load Amps (FLA) rating. If both motors run at the same time, you can use one 4 pole contactor rated at combined load, then split the power after the contactor through separate overloads to each motor. The control circuit becomes x----Stop----Run-----OL1-----OL2-----contactor coil-------x

Where x is the two 120v outputs of the transformer,

Stop is just the stop switch

OL1 is the switch contacts on the overload heater to motor 1

OL2 is the switch contacts on the overload heater to motor 2

Run is a little trickier, it is

--RS--

| |

--| |----

| |

--C4--

Basically the run switch (RS) in parallel with the 4th set of contacts on the contactor (C4).

Hopefully in this case C4 doesn't correspond to explosives

Ah well, the html processor eats my spaces on the RS/C4 diagram. Apparently the [PRE] tag doesn't work here. Grr.

I will probably salvage the transformer as I *just* put it in.

Yes, both motors usually run at the same time. The upper motor should be powered from the main circuit as it shouldn't ever be able to run without the whole mill being powered on. It runs only the vertical spindle. The main motor powers the hydraulics of the mill (travel, lubrication, etc). The photos are only showing the primary control circuitry.

The secondary motor has it's own switching and contactor but, like the primary, it has been jumpered out. It uses a 2P2T switch to control forward and reverse on the spindle.