-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

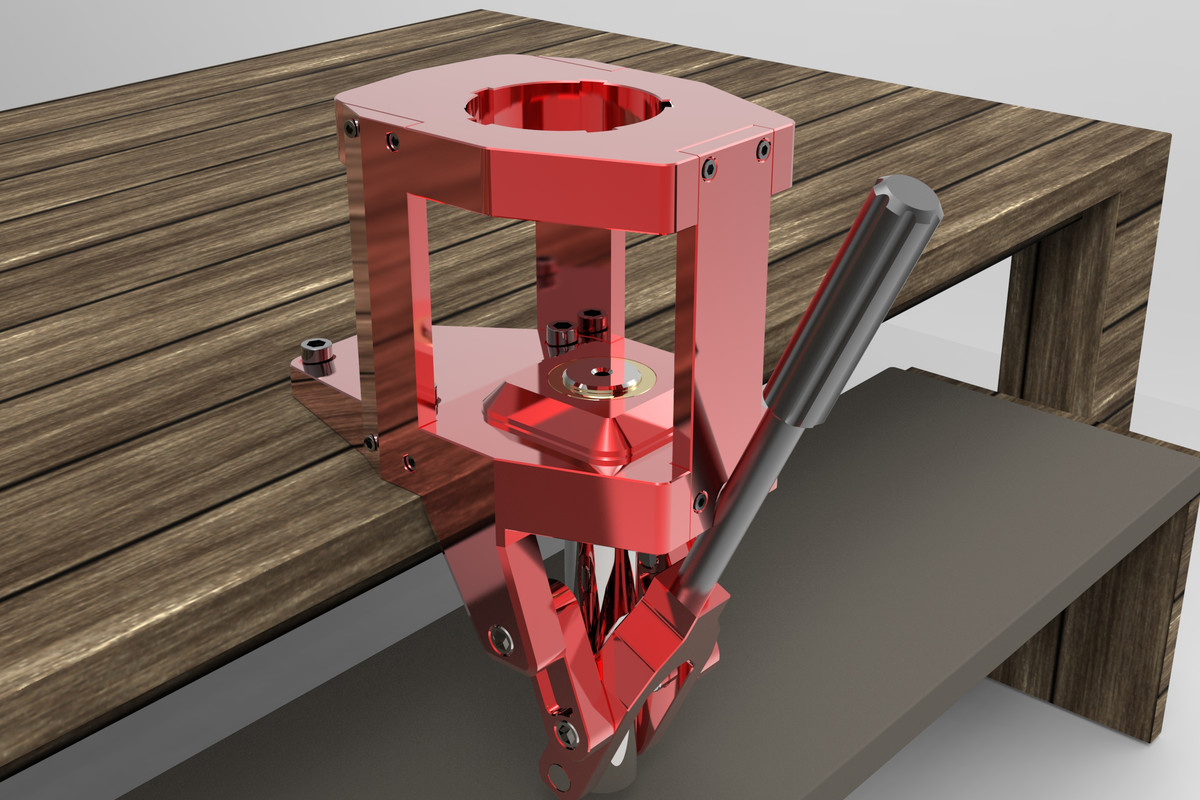

If You Built a Reloading Press...

- Thread starter silverhawk

- Start date

- Joined

- Apr 23, 2018

- Messages

- 6,509

Nice! Did you come up with a plan for cutting the center bore and lugs out of the action? I'd go bananas in my shop scratch-building Remmys if I could figure that one operation out. Broaching is the best I can come up with without major EDM capability.

Your press is admirable. I like the splined turret and the offset ram. Next time I decide I need another press, building my own will be the way to do it.

Your press is admirable. I like the splined turret and the offset ram. Next time I decide I need another press, building my own will be the way to do it.

- Joined

- Jan 6, 2017

- Messages

- 1,214

Nice! Did you come up with a plan for cutting the center bore and lugs out of the action? I'd go bananas in my shop scratch-building Remmys if I could figure that one operation out. Broaching is the best I can come up with without major EDM capability.

Your press is admirable. I like the splined turret and the offset ram. Next time I decide I need another press, building my own will be the way to do it.

I'd always though that If I got a chance to build some actions, I'd use drill and ream the hole first, machine the outside, then broach the raceways. Or, maybe buy and EDM setup.

For now, just working on my CAD skills

- Joined

- Dec 6, 2015

- Messages

- 807

I'm definitely curious on broaching the log raceways. I've thought about mark_f and his efforts on EDM for this, but I think broaching would be the simplest, easiest for a novice like me. How would you build the broach? Material?

Sent from my SM-T500 using Tapatalk

Sent from my SM-T500 using Tapatalk

- Joined

- Jan 6, 2017

- Messages

- 1,214

I'd make a mandrel with a milled keyway, to fit into the bore and probably grind a broach from HSS, to fit the shape of the raceway.

I've also considered a shaper, with some custom made tooling,

or even making an oversized adjustable cut rifling head. I think it would cut some nice raceways. Adjust the depth about .005" per pass. It would take awhile, but supposedly they work well.

I've also considered a shaper, with some custom made tooling,

or even making an oversized adjustable cut rifling head. I think it would cut some nice raceways. Adjust the depth about .005" per pass. It would take awhile, but supposedly they work well.

- Joined

- Nov 17, 2020

- Messages

- 1,723

Study Robert ChambardI'd make a mandrel with a milled keyway, to fit into the bore and probably grind a broach from HSS, to fit the shape of the raceway.

I've also considered a shaper, with some custom made tooling,

or even making an oversized adjustable cut rifling head. I think it would cut some nice raceways. Adjust the depth about .005" per pass. It would take awhile, but supposedly they work well.

- Joined

- Apr 23, 2018

- Messages

- 6,509

Study Robert Chambard

As far as I know, Chombart didn't publish books, but was a fan of 3-lug bolt designs. He was an active forum guy for a long time before he passed. Very knowledgeable.

- Joined

- Jan 6, 2017

- Messages

- 1,214

Study Robert Chambard

I have a neighbor/friend named Cliff Labounty who's well known for his barrels and rifling machines. I made one of the parts that are on the CNC cut rifllers he made for Benchmark and Kreiger.

I've talked this idea over with him, and got some good pointers on designing a head based on his rifling heads. I'll check out Robert Chambard and see what I can learn.

- Joined

- Nov 26, 2017

- Messages

- 1,515

Love my Benchmark barrel on my F-Class rifle. Didn't know that the rifling machine was built right here in our area.I have a neighbor/friend named Cliff Labounty who's well known for his barrels and rifling machines. I made one of the parts that are on the CNC cut rifllers he made for Benchmark and Kreiger.

I've talked this idea over with him, and got some good pointers on designing a head based on his rifling heads. I'll check out Robert Chambard and see what I can learn.