-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

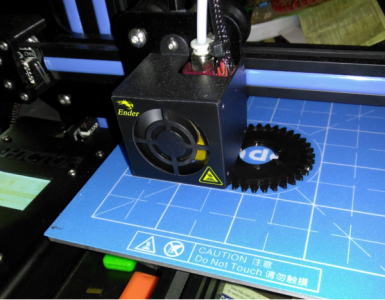

If you need gears... Print them...

- Thread starter Ray C

- Start date

- Joined

- Apr 26, 2014

- Messages

- 242

I watched this last night - the Atlas ran pretty well with the printed gears!

- Joined

- Nov 16, 2012

- Messages

- 5,596

I watched this last night - the Atlas ran pretty well with the printed gears!

I'd imagine it improves the sound quite a bit.

At the age of 5 or 6, my dad had me working in his shop and by the time I was 7, I was using the 15x54 LeBlond. From the age of 22 to roughly 40, I didn't touch anything shop related. Upon setting-up a garage shop, my starter lathe was an Atlas 618. It took a good long adjustment phase for me

, and the lathe was eventually rebuilt one piece at a time

, and the lathe was eventually rebuilt one piece at a time Ray

I'm printing a 36 tooth test gear right now. It's pla, but a good test as to the abilities to print, and how this gear would respond. It's one of the two gears on the foward reverse lever that seem to wear so much.

- Joined

- Sep 28, 2013

- Messages

- 4,302

nice! I have both an Altlas 618 and a 3D printer. I also have a full set of change gears too, but it would be an interesting idea to make up a series of cassettes with the gears premounted to a banjo for the common pitches (18, 20, 32 are ones I'd use a bunch). Not sure I do enough threading to justify the time, but at least the cost of the gears won't be a limiting factor!

- Joined

- Nov 16, 2012

- Messages

- 5,596

nice! I have both an Altlas 618 and a 3D printer. I also have a full set of change gears too, but it would be an interesting idea to make up a series of cassettes with the gears premounted to a banjo for the common pitches (18, 20, 32 are ones I'd use a bunch). Not sure I do enough threading to justify the time, but at least the cost of the gears won't be a limiting factor!

Even if the cost of 3D printing were higher than getting scalped on eBay, you'd still be better off. I remember purchasing a couple replacement parts for the Atlas and upon arrival, discovered they were worn more than the ones on the lathe. So, of course, that expedited the purchase of a mill -so I could make parts for the lathe... -Sigh...

Ray

- Joined

- Sep 28, 2013

- Messages

- 4,302

yeah, that's always a worry too. Even in ABS with 100% fill the largest gear would still only cost ~30c to print (ignoring the cost of the printer of course). I've been really happy with my 618 - I sometimes wish I had a larger lathe, particularly with a larger spindle bore, but for the most part it's been great.

- Joined

- Jan 16, 2020

- Messages

- 8

At the age of 5 or 6, my dad had me working in his shop and by the time I was 7, I was using the 15x54 LeBlond.

See, I always thought you were spoiled when you were a youngster. Now you admitted it!!

BTW files and info here;

https://www.thingiverse.com/thing:143893/#files

A printable spindle thread protector here;

https://www.thingiverse.com/thing:2585891

https://www.thingiverse.com/thing:143893/#files

A printable spindle thread protector here;

https://www.thingiverse.com/thing:2585891