It feels so good to get that off my chest. ;-)

One of the symptoms is constantly searching out ways to improve the performance, and accuracy of the airguns. In that pursuit, I've come across a design for an O-Ring sealed piston cap. Someday I'd like to make them myself but for now I'll need to find a talented machinist to make one for me.. the finished cap will look something like this

Or this if done in Delrin or as is the case here, in Moly filled 6/6 nylon rod.

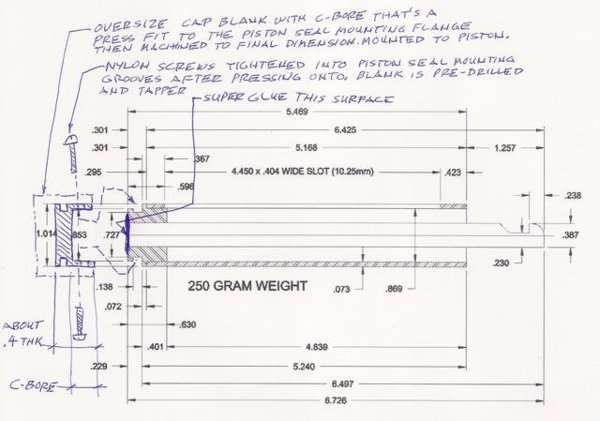

This is one of Ed's shop drawings for a similar 26mm piston he did some time ago.

The gun I'd be working with, an HW97K has a sliding compression tube and piston which I could send to whoever feels like tackling the project... the compression tube looks like this:

and the piston looks like this:

and the piston looks like this:

Looks like a challenging prospect to me but as I said, I'm not a machinist. What say the collective? Thanks for looking.

Steve

One of the symptoms is constantly searching out ways to improve the performance, and accuracy of the airguns. In that pursuit, I've come across a design for an O-Ring sealed piston cap. Someday I'd like to make them myself but for now I'll need to find a talented machinist to make one for me.. the finished cap will look something like this

Or this if done in Delrin or as is the case here, in Moly filled 6/6 nylon rod.

This is one of Ed's shop drawings for a similar 26mm piston he did some time ago.

The gun I'd be working with, an HW97K has a sliding compression tube and piston which I could send to whoever feels like tackling the project... the compression tube looks like this:

Looks like a challenging prospect to me but as I said, I'm not a machinist. What say the collective? Thanks for looking.

Steve