- Joined

- Feb 1, 2015

- Messages

- 9,598

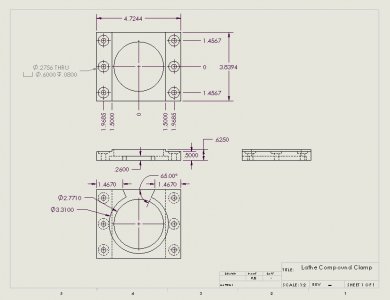

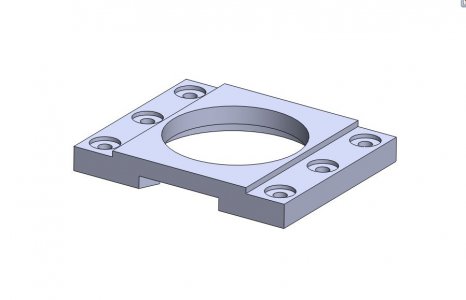

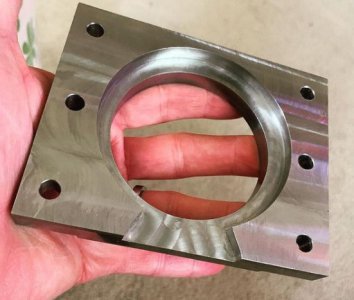

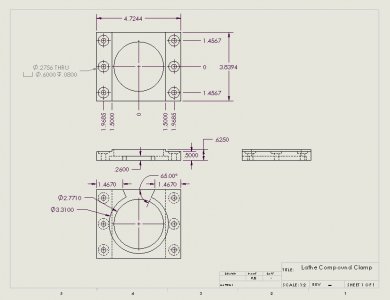

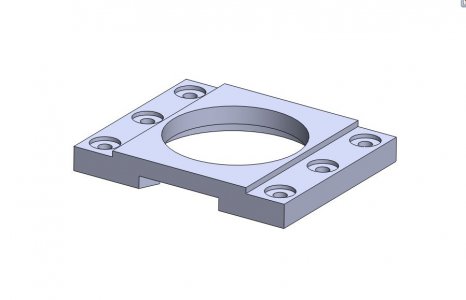

Several years ago, I designed a beefed up compound clamp for the Grizzly 9 x 19 lathe, based upon several designs I had seen on various websites. When I got my G0602, the first improvement that I made was to replace its compound clamp.

I made the clamp from a piece of 5/8" steel plate the same width as the cross feed slide and the length equal to twice the distance from the pivot hole to the front of the slide. The additional thickness gave increased rigidity and prevented bowing of the clamp, thereby improving clamping.

The original screw spacing was maintained for the four additional screws located at the corners of the clamp. The screw holes were counterbored and washers were made to keep the bottom of the screws slightly above the clamp Six hex head M8 screws with the heads faced down for clearance were used. A step was milled on either side of the clamp to permit necessary clearance for the hex head screws. A cutout at the front of the clamp provides visibility for the protractor dial without seriously compromising the clamp integrity.

In addition to making the clamp, I also added three more screws to the protractor dial to improve rigidity there.

The final assembly greatly enhances the rigidity of the tool post assembly.

I made the clamp from a piece of 5/8" steel plate the same width as the cross feed slide and the length equal to twice the distance from the pivot hole to the front of the slide. The additional thickness gave increased rigidity and prevented bowing of the clamp, thereby improving clamping.

The original screw spacing was maintained for the four additional screws located at the corners of the clamp. The screw holes were counterbored and washers were made to keep the bottom of the screws slightly above the clamp Six hex head M8 screws with the heads faced down for clearance were used. A step was milled on either side of the clamp to permit necessary clearance for the hex head screws. A cutout at the front of the clamp provides visibility for the protractor dial without seriously compromising the clamp integrity.

In addition to making the clamp, I also added three more screws to the protractor dial to improve rigidity there.

The final assembly greatly enhances the rigidity of the tool post assembly.