So after drilling many less than accurate holes on my cheap floor model drill press and using an even cheaper HF drill press vice. I started to look how to improve my chances.

I replaced the factory chuck with an older Jacobs 1/2 inch keyed chuck and that improved the run out substantially.

Then looking at the cheap HF vice there was nothing on it flat or square so to the mill it went, and with milling and new jaws that vice is now fairly flat within a thou or two, and that's ok for my work.

Now for the drill press table. I was able to shim that two within a thou or two also, again ok for my nuub level of accuracy. Measuring was done by sweeping a dial indicator mounted in the chuck.

But here is where I could use some ideas.

When I put downward pressure on the table, simulating a heavy drilling operation the table flexes down 4 or 5 thou. That is at the table edge, most likely about 2 thou at spindle.

I am thinking I would like to make a table support to add some down force rigidity.

First, is it worth it, or is .002 good enough?

Needs to be fairly quick and simple since height is adjusted often.

Does not need to be engaged for every operation. Only those requiring a bit more accuracy.

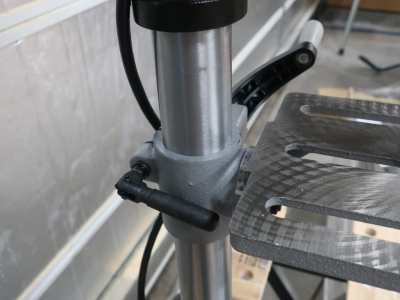

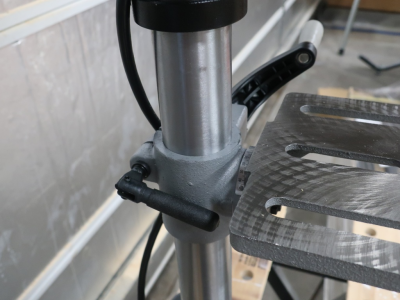

I'm thinking of a sliding ring that can be tightened on the column then a turnbuckle type bar that would push against the far side of the table at approximately 45 degrees.

My mill (Van Norman #12) does not have a quill so any drilling is with the knee. So I would like to make the drill press reasonably accurate if possible.

Any thoughts or other ideas? Has anyone had success doing something similar?

Long winded,

John in Minnesota!

Sent from my iPhone using Tapatalk

I replaced the factory chuck with an older Jacobs 1/2 inch keyed chuck and that improved the run out substantially.

Then looking at the cheap HF vice there was nothing on it flat or square so to the mill it went, and with milling and new jaws that vice is now fairly flat within a thou or two, and that's ok for my work.

Now for the drill press table. I was able to shim that two within a thou or two also, again ok for my nuub level of accuracy. Measuring was done by sweeping a dial indicator mounted in the chuck.

But here is where I could use some ideas.

When I put downward pressure on the table, simulating a heavy drilling operation the table flexes down 4 or 5 thou. That is at the table edge, most likely about 2 thou at spindle.

I am thinking I would like to make a table support to add some down force rigidity.

First, is it worth it, or is .002 good enough?

Needs to be fairly quick and simple since height is adjusted often.

Does not need to be engaged for every operation. Only those requiring a bit more accuracy.

I'm thinking of a sliding ring that can be tightened on the column then a turnbuckle type bar that would push against the far side of the table at approximately 45 degrees.

My mill (Van Norman #12) does not have a quill so any drilling is with the knee. So I would like to make the drill press reasonably accurate if possible.

Any thoughts or other ideas? Has anyone had success doing something similar?

Long winded,

John in Minnesota!

Sent from my iPhone using Tapatalk