- Joined

- Nov 12, 2022

- Messages

- 3

Hello,

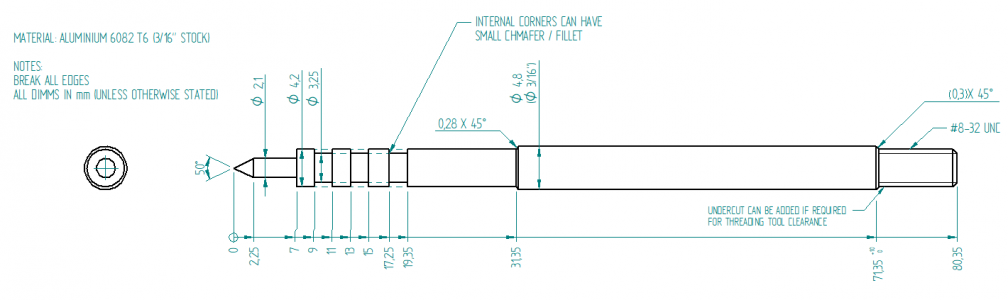

I've been struggling to find anywhere local with a lathe to turn this part and I was wondering if anyone here would be able to help me out?

I'm in the UK if that makes a difference.

The grade of material shouldn't be to critical and I have designed it from a standard stock size to hopefully make things easier to source and flip in the chuck.

I'm not sure about the feasibility threading the end up to the next face but an undercut can always be added to allow the tool some clearance (so long as it doesn't dramatically weaken the part)

Thanks again!

I've been struggling to find anywhere local with a lathe to turn this part and I was wondering if anyone here would be able to help me out?

I'm in the UK if that makes a difference.

The grade of material shouldn't be to critical and I have designed it from a standard stock size to hopefully make things easier to source and flip in the chuck.

I'm not sure about the feasibility threading the end up to the next face but an undercut can always be added to allow the tool some clearance (so long as it doesn't dramatically weaken the part)

Thanks again!