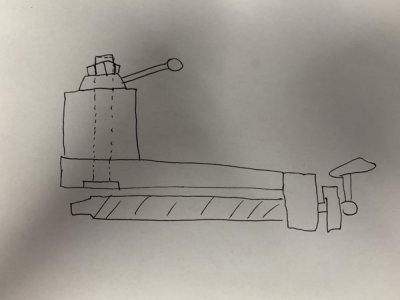

Hey guys, picked up my first ever 3-in-1 smithy It's the CB 1220 XL. I paid 500 bucks for the unit, the bench and all the tooling. So i couldn't say no. I went through the machine and everything seems tight. I adjusted the gibs and modified the cross slide drive screw. I added two springs to the drive nut adjuster mechanism to help keep tension on the drive screw. This is helping a little but am finding it loosens after a bit of use. so i get play in my cross slide. I did add the AXO quick change tool holder, I made a custom extended M10x1.5 bolt to mount it. It's identical to the origional mounting bolt but longer.

Anyways, the main issue i'm having is when I go to take a 10 thousands cut, it seems to be pretty close. I measure the cut depth with calipers and it seems good. When i go to take 15+ thousands it becomes wildly inaccurate. for example, a 15 thousands cut will be 28 thousands when i measure the cut depth. Is there anything I can do about this, or is this just the nature of the beast with these machines? I was thinking my best bet may be to add a DRO, or Maybe zero my cut depth every single cut instead of continuing the turn as i go.

Anyways, the main issue i'm having is when I go to take a 10 thousands cut, it seems to be pretty close. I measure the cut depth with calipers and it seems good. When i go to take 15+ thousands it becomes wildly inaccurate. for example, a 15 thousands cut will be 28 thousands when i measure the cut depth. Is there anything I can do about this, or is this just the nature of the beast with these machines? I was thinking my best bet may be to add a DRO, or Maybe zero my cut depth every single cut instead of continuing the turn as i go.