Hi folks,

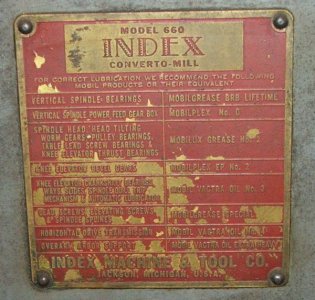

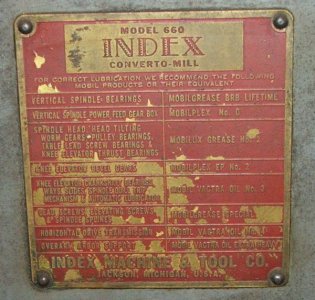

I've been lurking around, and have found some great information to help me with my recently purchased 1965 Index 660. It is a combination vertical mill and horizontal mill. The vertical head is like a model 645. The horizontal portion seems to be much like the model 60. It mostly all works, but I am in the process of disassembly to clean out the old grease, etc. I thought that I'd post up some pictures, and let you know that I may be asking for some advice during the rebuild.

I've been lurking around, and have found some great information to help me with my recently purchased 1965 Index 660. It is a combination vertical mill and horizontal mill. The vertical head is like a model 645. The horizontal portion seems to be much like the model 60. It mostly all works, but I am in the process of disassembly to clean out the old grease, etc. I thought that I'd post up some pictures, and let you know that I may be asking for some advice during the rebuild.