- Joined

- Aug 1, 2022

- Messages

- 137

I just picked this mill up yesterday. It was almost a 200 mile round trip but I got it home in one piece.

I think it’s an Index 40 mill. Hopefully you folks can look at the pictures and lend me your collective experience. Where would the model and serial numbers be located on this mill?

The mill came with a 1/3hp motor in the back that drives a shaft for the X axis feed. The stepped pulleys for the auto feed are in bad shape. No belt cover.

Drive motor is a Craftsman single phase “General Purpose” motor. The specs are no longer visible.

Also came with a Universal Eng. Co. Z #9 B&S collet chuck stuck to the B&S 9 taper. Currently soaking the spindle with Ed’s Red (a solution with equal parts Mineral Spirits, Kerosene, ATF, and Acetone), to see if I can get that chuck off later.

There appears to be some mechanism to automatically feed the quill. I can’t figure out how to engage the lever which engages the gear. The lever could be too gunked up to properly engage, as it really doesn’t have much of a throw to it. On top of the quill auto feed mechanism, there is a belt pulley (in bad shape) that isn’t connected to anything (no belt). Does one of the steps on the spindle pulley or middle pulley, or even the motor pulley engage the auto quill feed pulley?

Rotating the head: I loosened the 2 bolts and tried turning the square keyed mechanism at the back of the mill. Not budging. I’m thinking this is the proper way to turn the head. Or is it strictly a manual operation and the head is just stuck? If so, what does that crank at the back of the mill do?

I’ll need to figure out the wiring as I suspect the fuses are bypassed when the previous owner swapped out the original 3 ph motor with a 1 ph motor.

I think I’ll disassemble clean/lubricate and change out the spindle bearings on this mill. I don’t want to strip/paint it. I want to keep/use the auto feed for X and Z. I may need to source parts for those. I need to test the feed motor too. I’ll need new belts as well.

There is a vise too. The only markings I can see is “Japan”. Also, a 5/8” Z collet and a 5/8” straight shaft drill chuck.

Ultimately, I’m eyeing a ER40 B&S9 chuck with a set of collets. I’m also looking at a set of B&S9 collets, but may nix that idea depending on how hard it is to remove that Z collet chuck that’s likely been stuck to the spindle for decades.

Picture time…

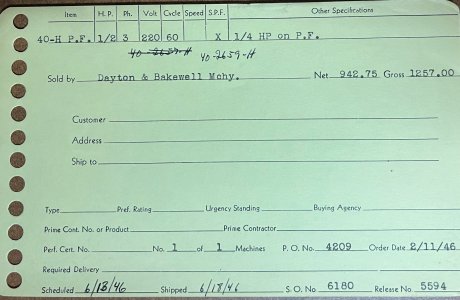

I think it’s an Index 40 mill. Hopefully you folks can look at the pictures and lend me your collective experience. Where would the model and serial numbers be located on this mill?

The mill came with a 1/3hp motor in the back that drives a shaft for the X axis feed. The stepped pulleys for the auto feed are in bad shape. No belt cover.

Drive motor is a Craftsman single phase “General Purpose” motor. The specs are no longer visible.

Also came with a Universal Eng. Co. Z #9 B&S collet chuck stuck to the B&S 9 taper. Currently soaking the spindle with Ed’s Red (a solution with equal parts Mineral Spirits, Kerosene, ATF, and Acetone), to see if I can get that chuck off later.

There appears to be some mechanism to automatically feed the quill. I can’t figure out how to engage the lever which engages the gear. The lever could be too gunked up to properly engage, as it really doesn’t have much of a throw to it. On top of the quill auto feed mechanism, there is a belt pulley (in bad shape) that isn’t connected to anything (no belt). Does one of the steps on the spindle pulley or middle pulley, or even the motor pulley engage the auto quill feed pulley?

Rotating the head: I loosened the 2 bolts and tried turning the square keyed mechanism at the back of the mill. Not budging. I’m thinking this is the proper way to turn the head. Or is it strictly a manual operation and the head is just stuck? If so, what does that crank at the back of the mill do?

I’ll need to figure out the wiring as I suspect the fuses are bypassed when the previous owner swapped out the original 3 ph motor with a 1 ph motor.

I think I’ll disassemble clean/lubricate and change out the spindle bearings on this mill. I don’t want to strip/paint it. I want to keep/use the auto feed for X and Z. I may need to source parts for those. I need to test the feed motor too. I’ll need new belts as well.

There is a vise too. The only markings I can see is “Japan”. Also, a 5/8” Z collet and a 5/8” straight shaft drill chuck.

Ultimately, I’m eyeing a ER40 B&S9 chuck with a set of collets. I’m also looking at a set of B&S9 collets, but may nix that idea depending on how hard it is to remove that Z collet chuck that’s likely been stuck to the spindle for decades.

Picture time…

Last edited: