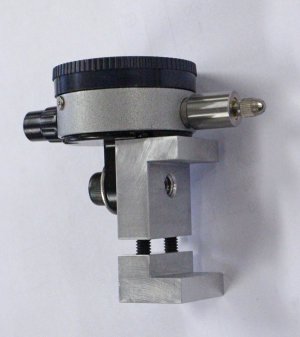

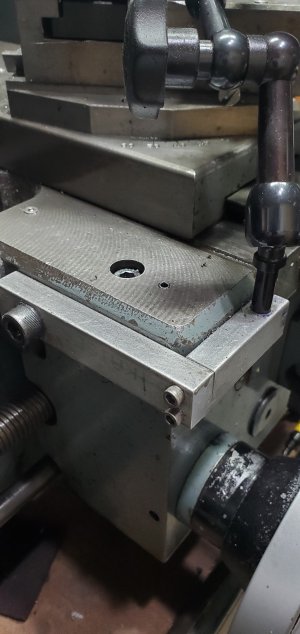

I needed a higher degree of accuracy on my cross slide for a recent (tool post grinding) job so made this clamp fixture for my 1.5" dial tenths indicator. There isn't a great spot to mount dials anywhere on the cross slide assembly without drilling holes or brackets. But this worked out pretty good. I re-mounted the dial back plate 90-deg so the mounting lug is perpendicular to the plunger as opposed to aligned. The plunger ball rests on the end of the cross slide casting so it sees absolute displacement. If the cross slide needs to be positioned more inward, I have screw-on plunger posts to extend the reach. If it needs to be positioned more outward I can screw in a spacer post between the mount & the lug. This particular indicator range is only 0.250" but was fine for this particular application.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Indicator Mount for Lathe Cross Slide

- Thread starter petertha

- Start date

- Joined

- Dec 27, 2014

- Messages

- 4,056

When I saw the T Slots on the PM lathe compound I was amazed that they hadn't been thought of sooner. I built a stop for single point threading (advance the tool for a new thread, then tweak the compound for tool increment,) and have plans for a back of the work cut-off. tool. Your indicator is a great idea. I'll have to 'gin one up.

- Joined

- Jul 8, 2018

- Messages

- 880

When I saw the T Slots on the PM lathe compound I was amazed that they hadn't been thought of sooner.

I've been toying with various ideas for adding T-slots to the 14" Logan. Making a plate that replaces the compound is straightforward, but I'd never use it. There's plenty of space to bolt something to the cross-slide behind (rear-way-wards) the compound, though it would cover the oil point and me pretty low. A smaller plate that replaces the QCTP would be convenient, though possibly less rigid and of course no QCTP.

Need to find the time travel setting on the lathe so I can go back to the 70s and convince Logan to add these features.

- Joined

- Jul 28, 2017

- Messages

- 2,368

Very nice! I hadn't even known it was possible to rotate the mounting lug on a DI. There have been times I cursed the standard orientation so this is a great tip.

And a clever add-on to make for myself.....

And a clever add-on to make for myself.....

Thanks guys, just a few follow up points.

The Mitutoyo dial bodies have 4 equally spaced screws so you can just unscrew them, rotate the back plate 90-deg & then the lug faces the other direction. One day I'm going to machine a dovetail mount back like a DTI. Strangely I haven t seen one like that in catalogs.

This is a 1.5" (nominal) diameter dial which is a smaller body compared to the more typical 2". My 2" kind of fits but not as good. The larger dial body comes close to interfering with the cross feed dial on the right side, at least on my lathe. I could offset the dial to the left to clear but I have this kind of jog in the apron casting and you can only go so far because the plunger has to contact the table obviously. I've seen adaptations where people make a new back for the dial & attach to a mag block that is typically used for test indicator arms. That's another option.

Here is a simple setup with DTI & short arm. Now its likely not a true displacement depending on the indicator arm angle & more limited range, but its a good way if you just wanted to establish a consistent datum or repeatable zero position for example.

In my case I was doing some tool post grinding so I felt I needed a solid measurement datum. The grinder is spinning pretty good & it does transmit a bit of hum through the compound assembly. The good news is the bracket dial was dead steady. When I tried the DTI the needle was buzzing so you had to take an average & hope the arm assembly wasn't drifting.

The Mitutoyo dial bodies have 4 equally spaced screws so you can just unscrew them, rotate the back plate 90-deg & then the lug faces the other direction. One day I'm going to machine a dovetail mount back like a DTI. Strangely I haven t seen one like that in catalogs.

This is a 1.5" (nominal) diameter dial which is a smaller body compared to the more typical 2". My 2" kind of fits but not as good. The larger dial body comes close to interfering with the cross feed dial on the right side, at least on my lathe. I could offset the dial to the left to clear but I have this kind of jog in the apron casting and you can only go so far because the plunger has to contact the table obviously. I've seen adaptations where people make a new back for the dial & attach to a mag block that is typically used for test indicator arms. That's another option.

Here is a simple setup with DTI & short arm. Now its likely not a true displacement depending on the indicator arm angle & more limited range, but its a good way if you just wanted to establish a consistent datum or repeatable zero position for example.

In my case I was doing some tool post grinding so I felt I needed a solid measurement datum. The grinder is spinning pretty good & it does transmit a bit of hum through the compound assembly. The good news is the bracket dial was dead steady. When I tried the DTI the needle was buzzing so you had to take an average & hope the arm assembly wasn't drifting.

Attachments

- Joined

- Jul 13, 2014

- Messages

- 1,051