- Joined

- Jul 20, 2014

- Messages

- 1,386

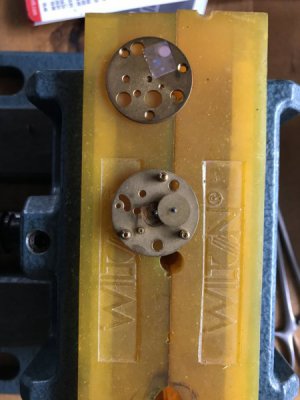

One of my Compac indicators was acting strange so I decided to try my hand.

It is not an easy task. It required a new hairspring/pinion assembly. These are tiny delicate parts.

Many careful steps and a new crystal. Works like new! The new hairpspring came with a protective disc which the original did not have.

The indicator will now not be susceptible to damage with the updated part.

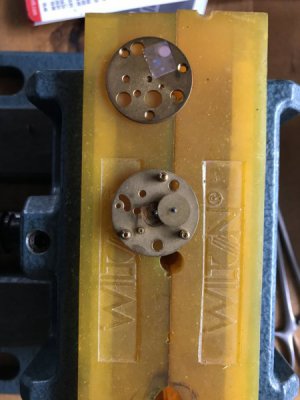

It is not an easy task. It required a new hairspring/pinion assembly. These are tiny delicate parts.

Many careful steps and a new crystal. Works like new! The new hairpspring came with a protective disc which the original did not have.

The indicator will now not be susceptible to damage with the updated part.