Looks like you are comparing a molded insert to a grounded (polished) insert. These are very different and so is the price.What does make a difference though is the actual inserts. It can be a little bit hard to tell just by looking at them, but there is a real difference between the $.25-$.75 inserts and the $15-$20 inserts (thats cents and dollars there).

Just to give you an idea of what the differences are, here is a look at an inexpensive import insert under a microscope. This insert was brand spanking new. You can see the cutting edge is already chipped and it is jagged. This one was probably about $1.

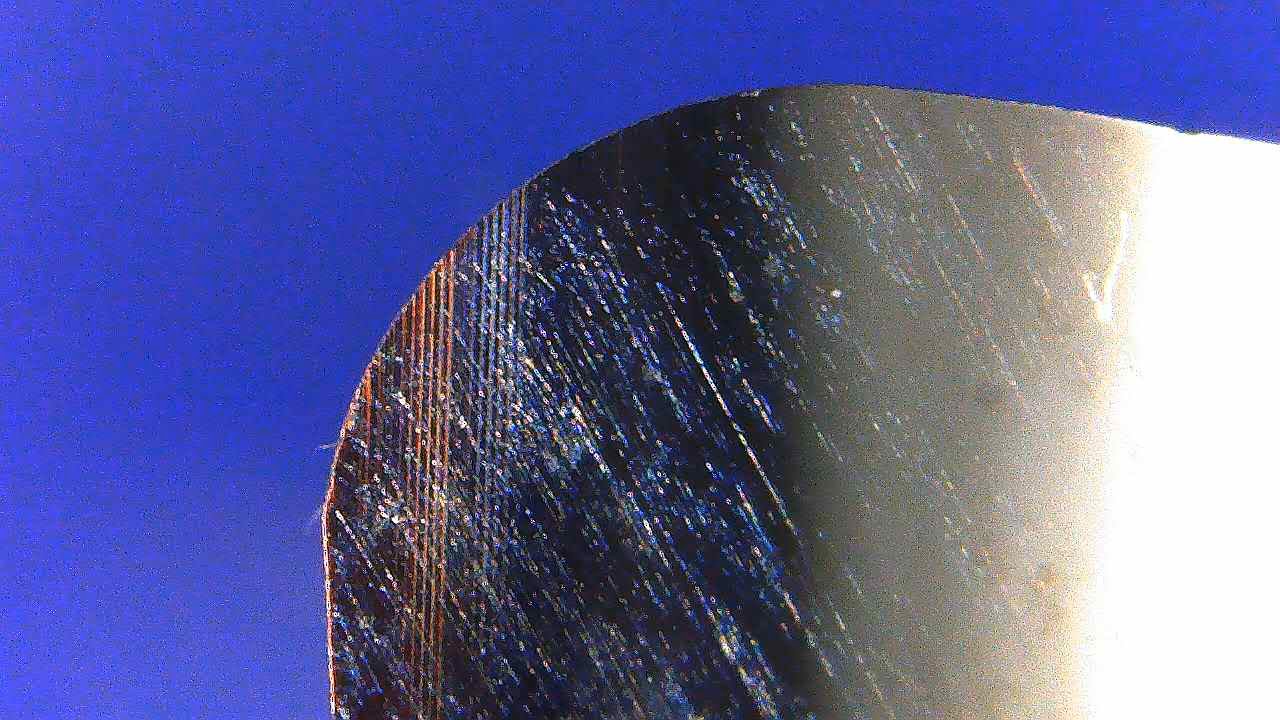

This one was a name brand insert that was about $20. Also brand new.

An important thing to consider though is that you might be happy with the cheap insert. It certainly gets the job done, surface finish just suffers a bit and I am betting the cutting edge doesn't last nearly as long.

A good place to start in my little experience is the BXA set from QMT https://www.precisionmatthews.com/s...ool-set-sized-for-bxa-quick-change-tool-post/ it comes with a good selection of tools and the quality seems decent. The grounded inserts for aluminium will also give a great surface with lighter cuts even on the harder to machine HR steel, CR 1018 etc.

Ariel