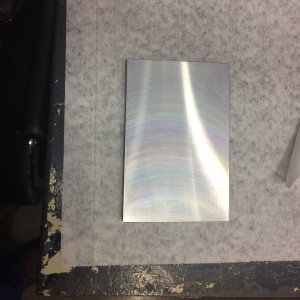

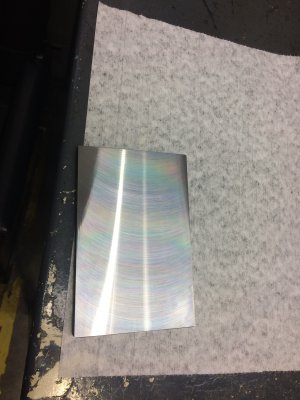

A few months ago I was needing to mill a 12” wide piece of steel. I noticed these cool fly cutter sets made by Suburban Tool but couldn’t justify purchasing the set. So, I made my own version....it uses a .750 diameter inserted boring bar. It works great!

Attachments

-

AE1D454E-73AC-40FE-8D5B-E21F088BA7F9.jpeg1.4 MB · Views: 81

AE1D454E-73AC-40FE-8D5B-E21F088BA7F9.jpeg1.4 MB · Views: 81 -

42A7D7B0-A0B1-4BAE-B1E6-D309C50A800E.jpeg860.1 KB · Views: 88

42A7D7B0-A0B1-4BAE-B1E6-D309C50A800E.jpeg860.1 KB · Views: 88 -

BF86913B-32C3-4C39-AB8D-F802AA4CBD7D.jpeg733.6 KB · Views: 82

BF86913B-32C3-4C39-AB8D-F802AA4CBD7D.jpeg733.6 KB · Views: 82 -

30712C80-EF63-46E0-A880-25869B2941E7.jpeg916.7 KB · Views: 82

30712C80-EF63-46E0-A880-25869B2941E7.jpeg916.7 KB · Views: 82 -

C6D21D99-D8AA-4C6F-A5F9-F18931CAFBEC.jpeg965.1 KB · Views: 80

C6D21D99-D8AA-4C6F-A5F9-F18931CAFBEC.jpeg965.1 KB · Views: 80 -

6728DFA8-4712-4D32-9A26-5EE89C9D5390.jpeg1.4 MB · Views: 77

6728DFA8-4712-4D32-9A26-5EE89C9D5390.jpeg1.4 MB · Views: 77