- Joined

- Dec 18, 2019

- Messages

- 6,437

Have a digital tach kit that I'd like to install in my mini-lathe. I will make an M27x1.5 hex nut to replace the circular jam nut on the spindle. (I know I can buy the nut for $5, but where's the fun in that?) The nut will be 12mm wide so I can mount a 12mm magnet. The 10mmx1 magnet that comes with the kit is a bit wimpy. The magnet will be JB Welded to the nut. (Once I test it for proper polarity!) I did wire the unit up and tested that it works. I used my demagnetizer and spun it and it measured a multiple of the RPM (due to the multiple of magnets!)

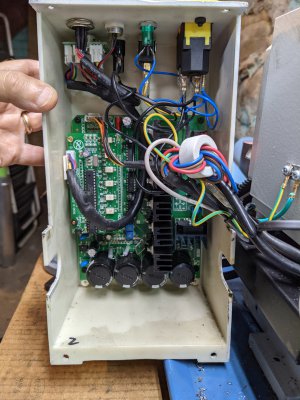

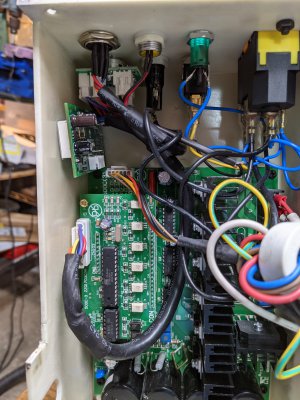

What I haven't yet figured out is where on the front plastic cover I can mount the display. There's not much real estate there. The control board is mounted to the front of the cover. I was thinking of the side, but that would require a huge cutout, greatly reducing the integrity of the plastic cover. In other words, the notch would be nearly the entire width of the side. Has anyone done a similar install on their mini-lathes? I'm trying to avoid a wart on top of the lathe. Horizontal surfaces are prime space, and I'd rather not have a plastic Bud box on top. Did you have to remove the display from the housing to install it? It looks pretty easy to pop the board and display out of the case.

In a couple of minutes I will post some pictures, so there's some context.

What I haven't yet figured out is where on the front plastic cover I can mount the display. There's not much real estate there. The control board is mounted to the front of the cover. I was thinking of the side, but that would require a huge cutout, greatly reducing the integrity of the plastic cover. In other words, the notch would be nearly the entire width of the side. Has anyone done a similar install on their mini-lathes? I'm trying to avoid a wart on top of the lathe. Horizontal surfaces are prime space, and I'd rather not have a plastic Bud box on top. Did you have to remove the display from the housing to install it? It looks pretty easy to pop the board and display out of the case.

In a couple of minutes I will post some pictures, so there's some context.