- Joined

- Sep 12, 2020

- Messages

- 56

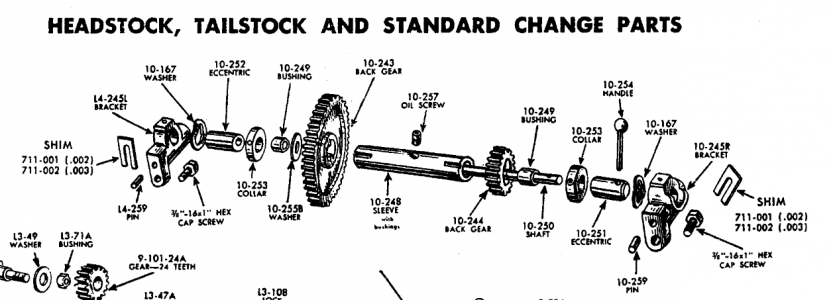

Looks like a guy on ebay is making some replacements out of aluminum... I may try and steel his design.

They have a used one on there for 99$ too. Man that feels expensive.

Edit: How precise do the holes in this piece need to be? Could I just drill them (without using a reamer)? I should be able to fabricate this on my mill.

Edit #2: This guy sells one with an aluminum case and steel gears - http://www.mymachineshop.net/product_p/10021.htm

They have a used one on there for 99$ too. Man that feels expensive.

Edit: How precise do the holes in this piece need to be? Could I just drill them (without using a reamer)? I should be able to fabricate this on my mill.

Edit #2: This guy sells one with an aluminum case and steel gears - http://www.mymachineshop.net/product_p/10021.htm

Attachments

Last edited: