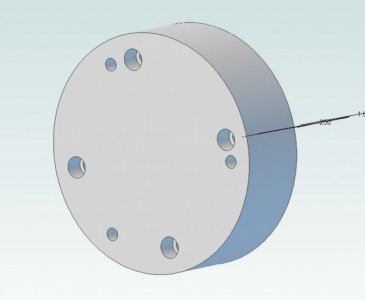

My little lathe has a fixed 4 inch 3 hole backplate, I have a 4 inch 4 jaw chuck I want to use but it has 4 holes not 3.

I was going to make an adapter as I am struggling to find anything here in Australia that will work. That will go from the 3 to 4 hole layout but I was looking at the bore on the lathe and I realised its an MT3.

Is it a bad practice to mount a chuck on a MT3? If not is there a morse taper that will fit the bore of the chuck. I quickly measured it and its 22mm .8661 inches.

Sorry if my terminology is wrong... Hopefully, I am making sense.

PS if anyone knows of a suitable adapter I'd also be interested as long as shipping isn't prohibitive.

Thanks

joez71

I was going to make an adapter as I am struggling to find anything here in Australia that will work. That will go from the 3 to 4 hole layout but I was looking at the bore on the lathe and I realised its an MT3.

Is it a bad practice to mount a chuck on a MT3? If not is there a morse taper that will fit the bore of the chuck. I quickly measured it and its 22mm .8661 inches.

Sorry if my terminology is wrong... Hopefully, I am making sense.

PS if anyone knows of a suitable adapter I'd also be interested as long as shipping isn't prohibitive.

Thanks

joez71