- Joined

- May 27, 2016

- Messages

- 3,469

I decided to plunge into the budget end of quick-change toolposts offerings with a pre-Halloween splurge.

Maybe not too exciting. I had considered this stuff might go into Member's Hangout!

It's the case of two lathes. One in bits being restored. A hiatus all about getting the outhouse/hideout/man cave/machine shop built and up. I need to do what limited work I can on the remaining lathe, in a space becoming ever more squeezed because of the various temporary building-related clutter. Not the time to go mad on the best most very expensive!

If the QCTP turns out to be a disappointment, then something else will be put on the other lathe, but I have had enough of the lantern post, and the square "slow change with shims" toolpost. Sure, I will keep the lantern one, for those times when one has to get in close to the end of a bar, and the TP would bump on stuff otherwise.

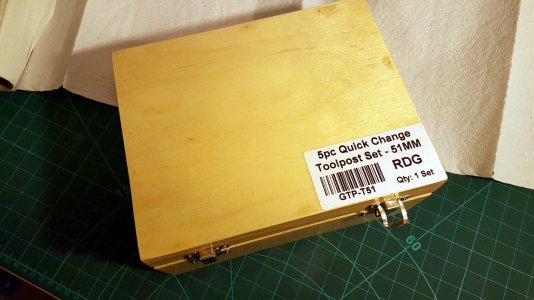

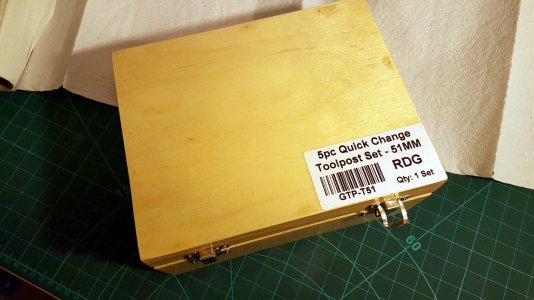

The toolpost is an offering from RDG Tools in UK, though they do sell on eBay, and they do ship international. The kit itself is marked RDG, but for all I know, it came from China/India/ Taiwan. It might even be British, but at the price, I somehow doubt it. The 51mm post (meaning 2") is the wedge type. £104.17 translates to $136.08.

In UK, we have VAT (a sales tax) 20%, that brings it to £125, but you would not have to pay that.

--> https://www.rdgtools.co.uk/acatalog/BOXFORD-TI-QUICK-CHANGE-TOOLPOST-SET--51mm--12169BOX.html

Ahh.. BOXFORD, you say. Yes. it seems BOXFORD was pretty much a SOUTH BEND CLONE, in almost all except the name label!

It comes in a wooden box with a place for each piece. All in little plastic bags, and all greased up.

__

__

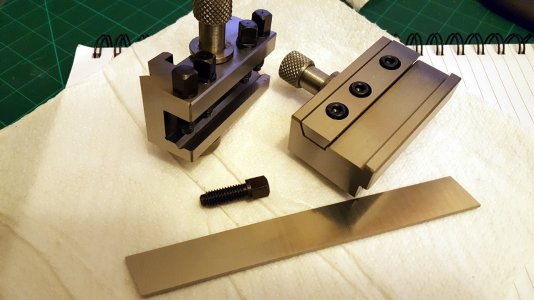

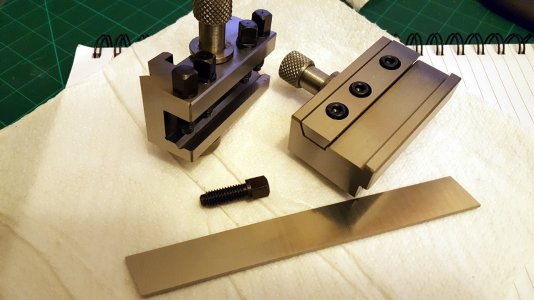

What's in there?

The QCTP body, 3" x 3" x 2". it might be close to AXA

Two regular tool holders with up to 16mm clearance (0.63")

One tool holder with a bottom Vee, to hold a boring bar.

One tool holder with a clamp slot to take a parting tool.

3 of the tools each get a spare black clamping screw.

There is the little plated T-bar with square socket, for tightening.

You get a free parting-off tool. Steel type is HSS.

__

__

So all parts ground and hardened. OK. It's not going to impress a horologist with his magnifier, but it looks OK for the purpose.

The mounting hole, allegedly 5/8", is actually 0.631 on the bottom, and 0.619 for the collar at the top.

The bottom of the tool holder "shelf" is 0.31 above the base. It will fit South Bend 9s, and probably all else that wants AXA

__

__

I scaled the pics to 1280 x 720, but I think we see all we need to.

Now the question is.. have I shelled out £125 (including VAT), on kit that I am going to have to purchase again? I think maybe this time, it might be OK. Edges beveled, seems hard as hell. Stoning the underside revealed almost zero surface grinder pattern. Just slight ribs shinys near the holes line. Whatever it is, it is magnitudes better than the compound it sits on!

So now you can all tell me that at that price, even the Chinese would shrug and give it a miss!

Maybe not too exciting. I had considered this stuff might go into Member's Hangout!

It's the case of two lathes. One in bits being restored. A hiatus all about getting the outhouse/hideout/man cave/machine shop built and up. I need to do what limited work I can on the remaining lathe, in a space becoming ever more squeezed because of the various temporary building-related clutter. Not the time to go mad on the best most very expensive!

If the QCTP turns out to be a disappointment, then something else will be put on the other lathe, but I have had enough of the lantern post, and the square "slow change with shims" toolpost. Sure, I will keep the lantern one, for those times when one has to get in close to the end of a bar, and the TP would bump on stuff otherwise.

The toolpost is an offering from RDG Tools in UK, though they do sell on eBay, and they do ship international. The kit itself is marked RDG, but for all I know, it came from China/India/ Taiwan. It might even be British, but at the price, I somehow doubt it. The 51mm post (meaning 2") is the wedge type. £104.17 translates to $136.08.

In UK, we have VAT (a sales tax) 20%, that brings it to £125, but you would not have to pay that.

--> https://www.rdgtools.co.uk/acatalog/BOXFORD-TI-QUICK-CHANGE-TOOLPOST-SET--51mm--12169BOX.html

Ahh.. BOXFORD, you say. Yes. it seems BOXFORD was pretty much a SOUTH BEND CLONE, in almost all except the name label!

It comes in a wooden box with a place for each piece. All in little plastic bags, and all greased up.

__

__

What's in there?

The QCTP body, 3" x 3" x 2". it might be close to AXA

Two regular tool holders with up to 16mm clearance (0.63")

One tool holder with a bottom Vee, to hold a boring bar.

One tool holder with a clamp slot to take a parting tool.

3 of the tools each get a spare black clamping screw.

There is the little plated T-bar with square socket, for tightening.

You get a free parting-off tool. Steel type is HSS.

__

__

So all parts ground and hardened. OK. It's not going to impress a horologist with his magnifier, but it looks OK for the purpose.

The mounting hole, allegedly 5/8", is actually 0.631 on the bottom, and 0.619 for the collar at the top.

The bottom of the tool holder "shelf" is 0.31 above the base. It will fit South Bend 9s, and probably all else that wants AXA

__

__

I scaled the pics to 1280 x 720, but I think we see all we need to.

Now the question is.. have I shelled out £125 (including VAT), on kit that I am going to have to purchase again? I think maybe this time, it might be OK. Edges beveled, seems hard as hell. Stoning the underside revealed almost zero surface grinder pattern. Just slight ribs shinys near the holes line. Whatever it is, it is magnitudes better than the compound it sits on!

So now you can all tell me that at that price, even the Chinese would shrug and give it a miss!

Last edited: