- Joined

- Aug 18, 2018

- Messages

- 6

I'm posting to introduce myself and to share my new lathe as a project. I've been doing hobby machining for a few years but have had an interest in it for longer. I rent an apartment and have slowly built a reasonably well outfitted machine shop in a little 1 car garage that is woefully underpowered. Over the past few years I've gotten to a point where I've been able to use my machine shop in a professional sense for when clients want prototyping work. Through my own hobby and this client work I've progressed a bit, but have so so much to learn. I've worked my way up from a 7x10 to 7x14 to 8x16 to this newest acquisition and hopeful long-time ownership JET 1024P.

I thought it would be fun to do a better job at documenting the process of acquiring and refurbishing this lathe so I'm starting this thread.

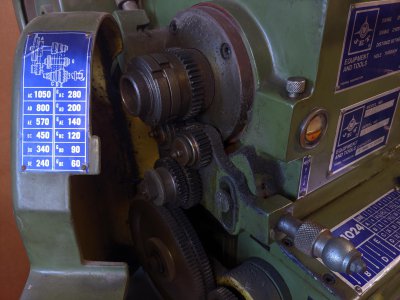

I had been hounding Craigslist wanting to find a replacement for my MX210V 8x16 lathe and shelter in place was in full swing. I saw this older JET 1024P lathe pop up on CL with a price that sounded high. At the same time, the action on CL was slowing way down because of pandemic precautions. Just for kicks I started looking into the lathe and was impressed with just how densely built it is and how many features it has. The quality Taiwanese manufacturing was also an interest point because I've been so disappointed by the abysmal manufacturing of my previous lathe. This lathe was there day after day and I started wondering if anyone at all had gone to see it. Also, analyzing the pictures it looked like it was barely used, and looked dry and dirty. The description was extremely sparse but my interest was there. So sparing you more words, I went to go see it for myself after it had been up for 25+ days.

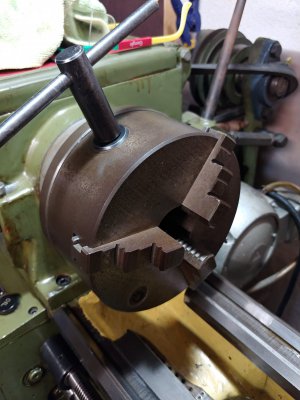

The lathe was in an old family owned jewelry manufacturing facility and this mother and son were getting rid of it. The guy told me his dad bought it brand new and maybe used it 5 times. They let me look through all the stuff and check out the lathe. It was totally complete, and covered in a ton of dust and some light surface rust. It included (I believe) every original accessory including the dinky little red toolbox that the spare parts came in. It had the change gears to switch between metric and standard, lathe jaws, various centers, a box of NOS Swedish HSS blanks, another box with tons of custom ground HSS tools, an Armstrong piston type QCTP, the original steady rest, and more. One of the best included bits was an uncut but threaded chuck backing plate blank. I've heard this lathe has a strange chuck mount threading so I take it that this is a pretty rare accessory to find new.

I tested it out and it all worked fine. I determined that this lathe was build like a little tank, had every bell and whistle I could want, and was absolutely the biggest piece of metal that could possibly (alright, barely) fit in my little 1-car garage. It needed a LOT of love and cleanup but it didn't have one dent or scratch on the ways, chuck, or the cross slide. No signs of abuse or wear. Loads of neglect, but that's different. I needed to try to get it! I did my best negotiating while strongly suspecting that I was the only person who had been by to check it out in a month. After some spirited back and forth, terms and conditions, they accepted my offer and I couldn't be more thrilled with the price we settled on. They also threw in a pretty sizeable amount of stock that Dad had purchased presumably for using on the lathe. I don't know exactly what I got but it's about 50+ lbs of new steel machining stock in various sizes!

Enlisting some coworker friends, we took a work truck with a liftgate over and nabbed the lathe, paid the kind folks, and drove it to my house. I'll include some shots of the condition that I acquired it in. I've started taking it apart, cleaning it, and getting it running smoothly, but that will come in the next installment.

Here it is in it's original habitat where it sat since the early 80's

Rusty and grimey but not damaged.

Work friends who are also great at rigging.

This is my tiny garage where I'm going to shoehorn this thing. I'm still going to try to park a car in here. We'll see how that goes.

I thought it would be fun to do a better job at documenting the process of acquiring and refurbishing this lathe so I'm starting this thread.

I had been hounding Craigslist wanting to find a replacement for my MX210V 8x16 lathe and shelter in place was in full swing. I saw this older JET 1024P lathe pop up on CL with a price that sounded high. At the same time, the action on CL was slowing way down because of pandemic precautions. Just for kicks I started looking into the lathe and was impressed with just how densely built it is and how many features it has. The quality Taiwanese manufacturing was also an interest point because I've been so disappointed by the abysmal manufacturing of my previous lathe. This lathe was there day after day and I started wondering if anyone at all had gone to see it. Also, analyzing the pictures it looked like it was barely used, and looked dry and dirty. The description was extremely sparse but my interest was there. So sparing you more words, I went to go see it for myself after it had been up for 25+ days.

The lathe was in an old family owned jewelry manufacturing facility and this mother and son were getting rid of it. The guy told me his dad bought it brand new and maybe used it 5 times. They let me look through all the stuff and check out the lathe. It was totally complete, and covered in a ton of dust and some light surface rust. It included (I believe) every original accessory including the dinky little red toolbox that the spare parts came in. It had the change gears to switch between metric and standard, lathe jaws, various centers, a box of NOS Swedish HSS blanks, another box with tons of custom ground HSS tools, an Armstrong piston type QCTP, the original steady rest, and more. One of the best included bits was an uncut but threaded chuck backing plate blank. I've heard this lathe has a strange chuck mount threading so I take it that this is a pretty rare accessory to find new.

I tested it out and it all worked fine. I determined that this lathe was build like a little tank, had every bell and whistle I could want, and was absolutely the biggest piece of metal that could possibly (alright, barely) fit in my little 1-car garage. It needed a LOT of love and cleanup but it didn't have one dent or scratch on the ways, chuck, or the cross slide. No signs of abuse or wear. Loads of neglect, but that's different. I needed to try to get it! I did my best negotiating while strongly suspecting that I was the only person who had been by to check it out in a month. After some spirited back and forth, terms and conditions, they accepted my offer and I couldn't be more thrilled with the price we settled on. They also threw in a pretty sizeable amount of stock that Dad had purchased presumably for using on the lathe. I don't know exactly what I got but it's about 50+ lbs of new steel machining stock in various sizes!

Enlisting some coworker friends, we took a work truck with a liftgate over and nabbed the lathe, paid the kind folks, and drove it to my house. I'll include some shots of the condition that I acquired it in. I've started taking it apart, cleaning it, and getting it running smoothly, but that will come in the next installment.

Here it is in it's original habitat where it sat since the early 80's

Rusty and grimey but not damaged.

Work friends who are also great at rigging.

This is my tiny garage where I'm going to shoehorn this thing. I'm still going to try to park a car in here. We'll see how that goes.