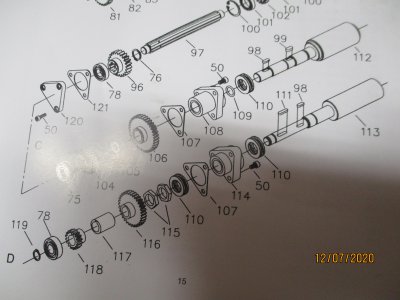

We had a similar problem at the local makerspace with a Jet 1440. I don't know what the exact problem was, but the gearbox had to be fully disassembled, and it took weeks to get it fixed. Every time I came in, I noticed a few more gears sitting on the work table, so progress was being made. Eventually, the lathe got put back together and it worked. They did not bother fixing the other lathe. They just said only use the one lathe for threading.

After seeing this, I swore that I would never get a lathe with a gearbox for my shop. The change gears are slightly more inconvenient, but no mysterious slipping problems. If the key is there and the teeth mesh, it is going to work. Just a little messy every time you need to swap gears.