- Joined

- Jun 7, 2019

- Messages

- 151

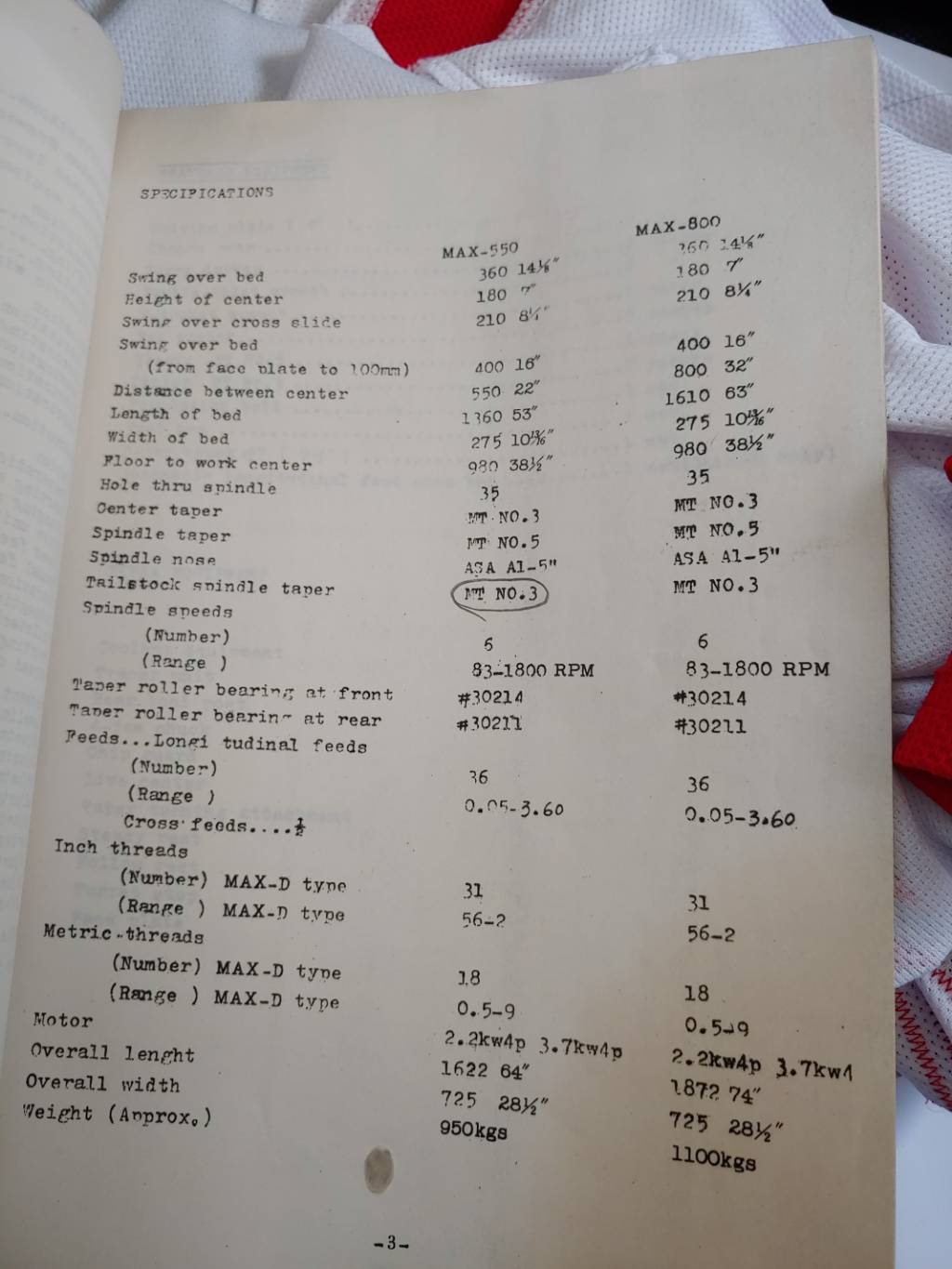

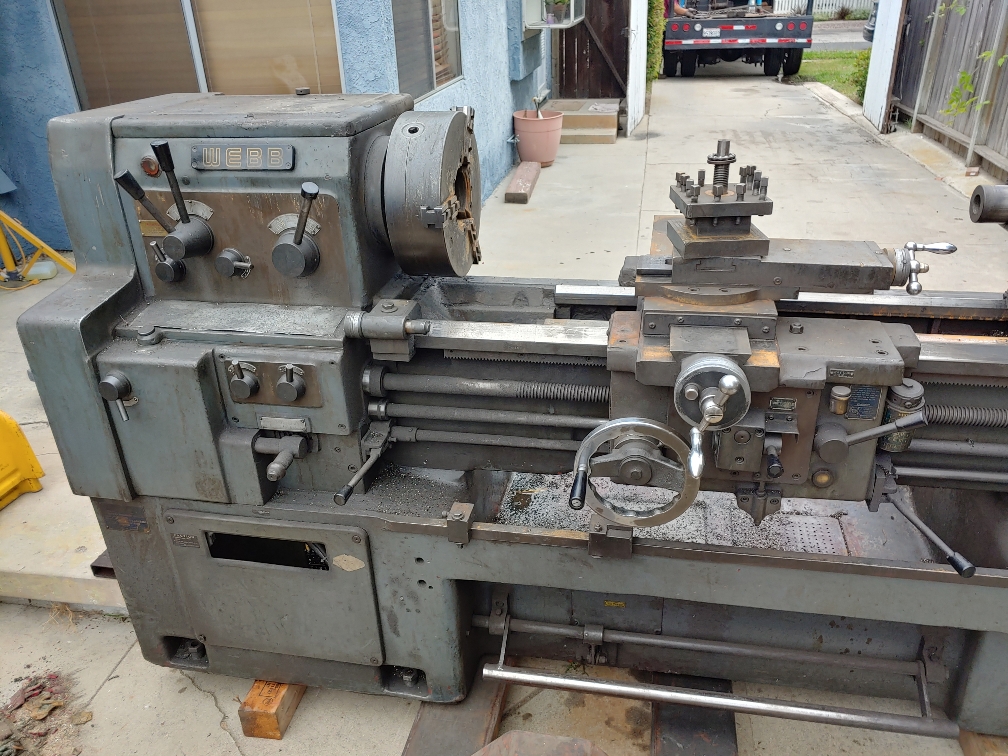

How did you measure it?Excellent, Jeff. I was looking at the factory checklist that came with mine. The spindle runout is shown as measured at 0.004mm, or 1.6 tenths. I measured it again, 40+ years later...it's exactly the same. Hard to believe, but I am really sold on these lathes.

Sent from my LM-V405 using Tapatalk