- Joined

- Jul 30, 2017

- Messages

- 475

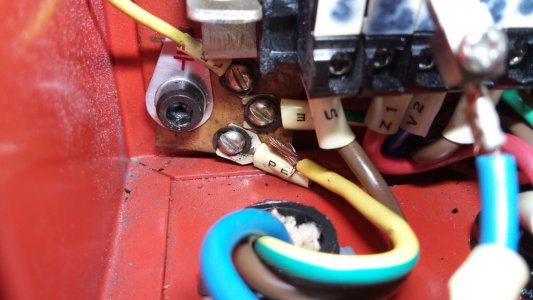

I looked at the manual and it calls out a D1-4 spindle so I must be wrong but I don't see any camlock cams on the rim of the chuck in the picture shown so how is the chuck being held onto the spindle?

Lets see a picture of the spindle with the chuck removed. The Frankenchuck photo is a little confusing.

John

I will post some clear photos of the spindle and chuck today when I get off work. The Cam locks are integrated into the spindle. and the chuck back plate is a conversion plate I think I read on bisons website.

My last working lathe was a 9X20 CM, so for me the size of this lathe is a bit intimidating and much bigger than the projects I have in store for it.

Last edited: